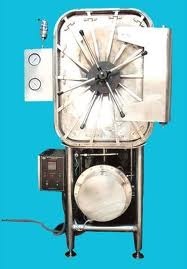

Vertical Autoclaves

Vertical Autoclaves Specification

- Type

- Vertical Autoclave

- Chamber Size

- 430 x 660 mm

- Outer Size

- 550 x 750 mm

- Design Pressure

- 2.2 kg/cm

- Working Pressure

- 1.2 kg/cm

- Design Temperature

- 134C

- Heat Uniform

- 1C

- Insulation

- Glass Wool

- Net Weight

- Approx. 120 kg

- Recording Parameters

- Digital Temperature and Pressure Recorders

- Spraying Mode

- Direct Steam Contact

- Inner Trolley

- Stainless Steel Perforated Basket

- Spraying Piping

- Stainless Steel Piping

- Sterilizing Temperature

- 121C

- Working Temperature

- 121C

- Sterilization Time

- 0~999 minutes (adjustable)

- Temperature Scope

- 105C~134C

- Piping System

- SUS 304/316 Stainless Steel

- Valves

- Safety Valve, Exhaust Valve, Drain Valve

- Accessories Included

- Tray Lifter, Extra Baskets

- Product Capacity

- 35 to 150 liters (models available)

- Voltage

- 220/230V AC, 50/60Hz

- Chamber Finish

- Polished/Mat Finish

- Control System

- Automatic PLC or Microprocessor based

- Material of Construction

- Stainless Steel 304/316

- Display

- Digital LED/LCD Display

- Vacuum System

- Not Available in Standard Models

- Sterilization Cycle Modes

- Standard, Liquid, and Custom

- Heating Element

- Immersion Type, Heavy Duty

About Vertical Autoclaves

Advanced Sterilization Technology

Our vertical autoclaves employ advanced digital controls, allowing users to select between standard, liquid, and custom sterilization cycles. The immersion-type heating element delivers superb heat distribution, while the stainless steel construction ensures durability and hygienic operation. Digital displays and recorders help maintain precise parameter control during every cycle.

User-Friendly Design and Accessories

Every unit comes with practical accessories such as tray lifters, extra baskets, and a stainless steel perforated basket trolley. Operation is simplified with an automatic PLC or microprocessor, providing peace of mind and allowing focus on other laboratory tasks. The easy-to-navigate interface and safe exhaust, drain, and safety valves contribute to smooth and safe use.

Safe, Efficient, and Reliable Sterilization

Designed with operator safety and sterilization efficacy in mind, our autoclaves feature glass wool insulation to retain heat, multiple safety valves, and robust construction. They achieve a working temperature of 121C, with heat uniformity at 1C, supporting sterilization needs for labs, hospitals, and research centers across India. Comprehensive digital monitoring ensures compliance and reliability.

FAQs of Vertical Autoclaves:

Q: How does the digital LED/LCD display enhance the operation of the vertical autoclave?

A: The digital LED/LCD display provides real-time monitoring of both temperature and pressure inside the chamber. This helps users to easily set and observe the sterilization process, ensuring precision, safety, and compliance with sterilization requirements.Q: What are the available sterilization cycle modes in these autoclaves and when should each be used?

A: The autoclave offers three sterilization cycle modes: Standard, Liquid, and Custom. The Standard mode is suited for general items, Liquid mode is designed for fluids, and the Custom mode can be adjusted for specific materials or research needs, ensuring effective and tailored sterilization outcomes.Q: Where can this vertical autoclave be installed for optimal performance?

A: These vertical autoclaves are best installed in laboratories, hospitals, or clinical research facilities with proper electrical connectivity (220/230V AC, 50/60Hz). The robust design and manageable outer size (550 x 750 mm) facilitate versatile placement without taking up excessive space.Q: How does the insulation and design of the autoclave benefit the user during sterilization cycles?

A: The chamber features glass wool insulation, which helps maintain internal temperature, reducing heat loss and energy consumption. Combined with a 1C heat uniformity, it ensures reliable sterilization while enhancing operator safety by keeping the exterior cooler.Q: What is the process for operating the autoclave and recording sterilization parameters?

A: Users load the materials onto the provided stainless steel perforated basket or with extra baskets, select the desired sterilization cycle via the digital interface, and start the process. The integrated digital temperature and pressure recorders automatically log sterilization parameters for quality assurance and documentation.Q: What are the main benefits of using a stainless steel 304/316 construction in these autoclaves?

A: Stainless steel 304/316 provides exceptional durability, corrosion resistance, and easy cleaning, ensuring a long service life and adherence to sterile conditions, which is crucial for laboratory and medical use.Q: Is a vacuum system included in the standard models of these vertical autoclaves?

A: No, a vacuum system is not available in the standard models. They use direct steam contact for sterilization, which is highly effective for most applications where pre-vacuum is not required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AUTOCLAVES Category

Table Top Autoclaves

Type : Other, Horizontal Table Top Autoclave

Chamber Size : 385 x 250 mm

Sterilizing Temperature : 121C

Valves : Safety valve, exhaust valve

Working Temperature : 105C 134C

Heat Uniform : 1C

Stainless Steel Cement Autoclaves

Type : Other, Front loading horizontal autoclave

Chamber Size : 550 x 350 x 400 mm

Sterilizing Temperature : 134C (max)

Valves : Stainless steel safety and exhaust valves

Working Temperature : 121C or 134C selectable

Heat Uniform : 1C distribution

Horizontal Rectangular Autoclaves

Type : Other, Horizontal Rectangular

Chamber Size : 1000 x 600 x 600 mm (customizable)

Sterilizing Temperature : 121C to 134C

Valves : Automated ball valves for inlet & outlet

Working Temperature : 121C

Heat Uniform : 1C throughout chamber

Horizontal Autoclaves

Type : Other, Automatic horizontal rectangular autoclave

Chamber Size : 1100 x 500 x 500 mm (other sizes on request)

Sterilizing Temperature : 121C standard, up to 134C for advanced cycles

Valves : Driven by pneumatic or electric actuator, SS316

Working Temperature : Up to 128C continuous

Heat Uniform : 1C across chamber

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry