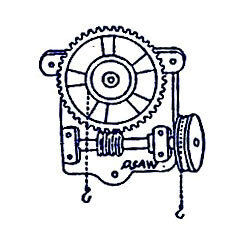

Worm and Worm Wheel

Worm and Worm Wheel Specification

- Feature

- Durable and reliable motion transfer

- Model No

- Standard Worm Gear

- Power Source

- Mechanical

- Warranty

- Depends on manufacturer

- Core Components

- Worm and Worm Wheel

- Accuracy

- Standard

- Automation Grade

- Manual

- Temperature Range

- Varies by material

- Capacity

- Varies by application

- Equipment Materials

- Metal

- Type

- Worm and Worm Wheel

- Usage

- Motion transfer power transmission

- Display Type

- None

- Dimension (L*W*H)

- Customizable

- Weight

- Varies by size

About Worm and Worm Wheel

Worm and Worm Wheel

(A) single

(B) double

(C) tripple

Worm and Worm Wheel (80 teeth cut worm gear)

FAQs of Worm and Worm Wheel:

Q: What is the accuracy level of the Worm and Worm Wheel product?

A: The accuracy of the Worm and Worm Wheel is standard.Q: What are the core components of the Worm and Worm Wheel product?

A: The core components of the Worm and Worm Wheel are Worm and Worm Wheel.Q: What is the warranty coverage for the Worm and Worm Wheel product?

A: The warranty for the Worm and Worm Wheel depends on the manufacturer.Q: What is the power source used for the Worm and Worm Wheel product?

A: The power source for the Worm and Worm Wheel is mechanical.Q: What is the feature that defines the Worm and Worm Wheel product?

A: The Worm and Worm Wheel is known for its durable and reliable motion transfer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Pulley Blocks

Feature : HeavyDuty

Core Components : Not available

Equipment Materials : Metal

Type : Pulley Block

Display Type : Not available

Usage : Material Handling

Flow Table :IS:712-1956

Feature : Designed as per IS:7121956

Core Components : Bronze Cone Metal Base Adjustment Knob

Equipment Materials : Bronze Metal

Type : Flow Table

Display Type : None

Usage : Testing building materials flow consistency

Working Model Of Belt Conveyor

Feature : Compact, easy assembly, visual demonstration

Core Components : Electric motor, frame, rollers, belt

Equipment Materials : Mild steel frame, plastic/rubber conveyor belt, aluminum rollers

Type : Portable demonstration conveyor

Display Type : Manual demonstration (No electronic display)

Queen Post Truss Model

Feature : Demonstrates load tolerance and structural stability

Core Components : Wood and metal fasteners

Equipment Materials : Wood and metal

Type : Structural Demonstration Model

Display Type : Physical model

Usage : Educational and training purposes

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry