Geneva Drive

Geneva Drive Specification

- Temperature Range

- Room Temperature Operation

- Automation Grade

- Manual or Semi Automatic

- Power Source

- Mechanical Input (Manual or Motor Driven)

- Measurement Range

- Step Angle Customizable (30180 per index)

- Capacity

- Customizable as per application

- Core Components

- Geneva Wheel, Driving Pin, Locking Disc, Shaft

- Accuracy

- Up to 0.05 mm per step

- Model No

- As per customer order / Standard/Custom

- Frequency

- As per Drive Design Specifications

- Type

- Mechanical Intermittent Motion Mechanism

- Usage

- Automation, Indexing System, Mechanical Timing

- Dimension (L*W*H)

- Standard Size: 150 mm x 110 mm x 95 mm (varies with model)

- Rotation Speed

- Up to 60 Cycles per Minute

- Finish

- Corrosion Resistant Surface Treatment

- Operating Life

- >10 Million Indexing Cycles

- Customization

- Available as per Application

- Output Torque

- Up to 250 Nm (Model Dependent)

- Operating Noise Level

- <50 dB

- Mounting Type

- Base or Flange Mounted

- Bearings

- Sealed Ball Bearing

- Number of Stops

- Standard: 4, 6, 8, 12 (Custom on Demand)

- Production Standard

- Conforms to ISO 9001:2015

- Application Industry

- Packaging, Printing, Automation, Textile, Robotics

About Geneva Drive

Key Features and Areas of Application

The Geneva Drive stands out for its ultimate accuracy up to 0.05 mm per step and user-friendly mechanical intermittent motion. Its robust design, reliable sealing, and customizable step angles (30180) fit diverse machineries in automation, textile, packaging, robotics, and printing. With base or flange mounting, its an excellent choice where precise indexing or mechanical timing is required, offering seamless integration across wide-ranging industrial areas and specialized OEM applications.

Delivery Timeline, Supply Capacity and Certifications

Handed over quickly for your urgent projects, Geneva Drive benefits from swift dispatch and robust supply ability spanning domestic and international needs. Advance expenditure planning helps streamline your procurement. Each unit is delivered with necessary certifications, including conformity to ISO 9001:2015 standards, ensuring top-notch product reliability. Our expedited delivery model minimizes downtime, emphasizing punctuality and consistent product availability for seamless integration into your workflow.

FAQs of Geneva Drive:

Q: How does the Geneva Drive benefit automation and indexing processes?

A: The Geneva Drive provides highly accurate intermittent motion, making it ideal for automation and indexing systems where precise positioning and timing are essential.Q: What are the standard and custom stop configurations available for Geneva Drive?

A: Standard models offer 4, 6, 8, and 12 stops, while custom stops can be provided on demand to fit unique application requirements.Q: When is the product typically handed over after confirming an order?

A: Delivery time is quick, typically handed over within a few days depending on customization and supply requirements. Advance purchase can further reduce dispatch timelines.Q: Where can the Geneva Drive be used effectively?

A: The Geneva Drive is excellent for industries including packaging, printing, automation, textile, and robotics, where precise step motion and mechanical timing are vital.Q: What is the process for customizing the Geneva Drive as per application needs?

A: Customization is available according to specific industry and operational requirements, with step angle, output torque, and mounting type adapted during the ordering process.Q: Is ISO certification available for Geneva Drive products?

A: Yes, all Geneva Drive units conform to ISO 9001:2015 production standards, ensuring trusted quality and certification for industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

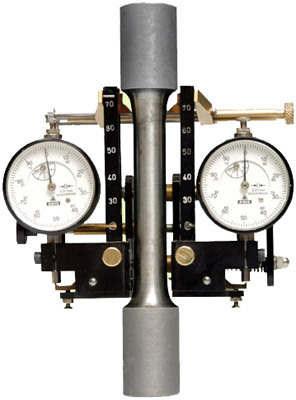

Extensometer

Automation Grade : Manual

Usage : Material Testing

Type : Mechanical Extensometer

Equipment Materials : Alloy Steel

Feature : High accuracy robust design

Core Components : Steel Aluminum

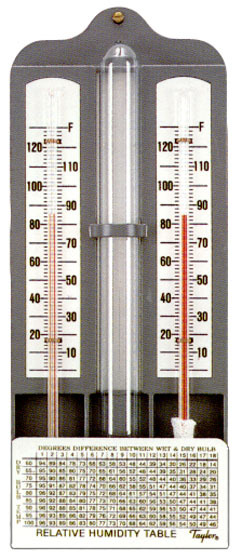

Wet & Dry Bulb Hydrometer

Automation Grade : Manual

Usage : Relative Humidity Measurement

Type : Wet & Dry Bulb Hydrometer

Equipment Materials : Plastic Glass

Feature : Measures Wet & Dry Bulb Temperature

Core Components : Glass tube Scale Relative Humidity Table

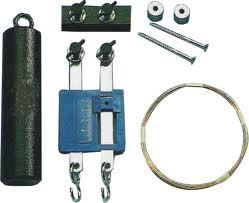

Young's Modulus Apparatus (Searle's Pattern)

Automation Grade : Manual

Usage : For determining Youngs modulus of materials

Type : Youngs Modulus Apparatus

Equipment Materials : Metal and plastic components

Feature : Durable construction; suitable for educational and laboratory use

Core Components : Metal frame screws clamping apparatus circular ring

Altimeter

Automation Grade : Manual

Usage : Aircraft altitude measurement

Type : Analog Altimeter

Equipment Materials : Metal Glass

Feature : Altitude measurement

Core Components : Dial Needles Casing

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry