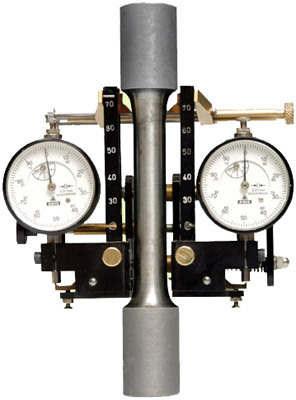

Tensile(Briquette)Testing Machine

Tensile(Briquette)Testing Machine Specification

- Automation Grade

- Manual

- Frequency

- 50 Hz

- Feature

- Accurate, Robust Construction, Easy to Operate

- Accuracy

- 1%

- Temperature Range

- Ambient

- Capacity

- 10 kN (1000 kgf)

- Power Source

- Manual

- Core Components

- Testing Screw, Scale, Loading Yoke, Weights, Fly Wheel

- Equipment Materials

- Cast Iron, Mild Steel

- Type

- Manually Operated Mechanical Testing Machine

- Usage

- Tensile Strength Testing of Cement Briquettes

- Display Type

- Dial Gauge Indicator

- Dimension (L*W*H)

- 720 x 250 x 700 mm

- Load Application Method

- Screw Driven with Flywheel

- Operating Environment

- Laboratory, Indoor

- Packing Type

- Wooden Crate Packing

- Grip Type

- Dual Briquette Judged Gripping

- Finish

- Powder Coated

- Application Area

- Civil Engineering, Cement Testing

- Operating Temperature

- 10C 45C

- Testing Standards

- IS: 269, 4031, ASTM C307

- Maximum Specimen Size

- 75 mm x 25 mm (Standard Briquette)

About Tensile(Briquette)Testing Machine

Widespread Commercial Applications and Suitability

The Tensile (Briquette) Testing Machine is perfectly suited for civil engineering laboratories, quality control centers, and cement manufacturing units. Its dominant design supports a wide range of commercial uses, from cement composition validation to quality assurance protocols. The machine is also ideal for research institutions focusing on material strength analysis, making it a dazzling choice for professionals seeking accuracy and reliability in tensile strength measurement of cement briquettes.

Premium Dispatching, Payment, and Packaging Terms

Our illustrious Tensile (Briquette) Testing Machine is dispatched using premium wooden crate packaging, guaranteeing safety during transit. We offer flexible payment terms, including advance payments and LC options, to ensure smooth transactions for all our clients. Deliveries are efficiently handled via our designated FOB port in India, and we provide sample policies to demonstrate product quality before bulk orders. Every process ensures precision and customer satisfaction from order placement to final shipment.

FAQs of Tensile(Briquette)Testing Machine:

Q: How is the Dual Briquette Judged Gripping system beneficial for testing?

A: The Dual Briquette Judged Gripping system ensures stable holding of standard briquette specimens, reducing slippage and boosting accuracy during tensile strength evaluations of cement samples.Q: What testing standards can be utilised with this machine?

A: This machine satisfies the requirements of IS: 269, 4031, and ASTM C307, making it a dominant choice for industry-standard cement tensile testing applications.Q: Where can this Tensile (Briquette) Testing Machine be effectively used?

A: It is highly suitable for commercial cement manufacturing plants, civil engineering laboratories, research institutions, and quality control set-ups requiring reliable tensile strength testing.Q: What is the process for installing and operating this equipment?

A: Installation is straightforward due to robust construction; simply set up in an indoor laboratory, ensure ambient temperatures between 10C and 45C, and operate using the manual screw-driven mechanism with flywheel and weights.Q: When should regular maintenance be performed on this machine?

A: Periodic maintenance is recommended based on usage intensity, typically every 612 months, to ensure accuracy and longevity of the machines core components such as the testing screw and loading yoke.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Extensometer

Feature : High accuracy robust design

Core Components : Steel Aluminum

Usage : Material Testing

Equipment Materials : Alloy Steel

Type : Mechanical Extensometer

Dimension (L*W*H) : 200 x 100 x 50 mm

King Post Truss Model

Feature : Lightweight Durable High strength

Core Components : Steel Iron

Usage : Construction and structural support

Equipment Materials : Steel

Type : Roof Truss

Dimension (L*W*H) : Variable based on project needs

Hydraulic Press Model

Feature : Compact design suitable for lab use

Core Components : Spring Handle Cylinder

Usage : Lab testing Industrial applications

Equipment Materials : Steel Cast Iron

Type : Manual Hydraulic Press

Dimension (L*W*H) : 400x300x500 mm

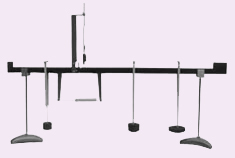

Shear Force Apparatus

Feature : Educational Apparatus for Measuring Shear Force

Core Components : Steel Base Measuring Setup

Usage : Educational and Laboratory Use

Equipment Materials : Steel Aluminum

Type : Shear Force Measurement Apparatus

Dimension (L*W*H) : Standard Dimensions

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry