Spur Gears

Spur Gears Specification

- Capacity

- Up to 2000 Nm torque transmission

- Measurement Range

- Module 1 to 10

- Core Components

- Teeth, Hub, Bore

- Power Source

- Mechanical drive system

- Feature

- Precision cut, high strength, corrosion resistant, durable

- Model No

- SG Series

- Accuracy

- DIN 8 to DIN 6

- Equipment Materials

- Alloy Steel, Cast Iron, Carbon Steel, Stainless Steel

- Type

- Spur Gear

- Usage

- Industrial machinery, automation, conveyors, gearboxes

- Dimension (L*W*H)

- Diameter: 50 mm to 600 mm; Module: 1 to 10

- Weight

- 1 kg to 35 kg

About Spur Gears

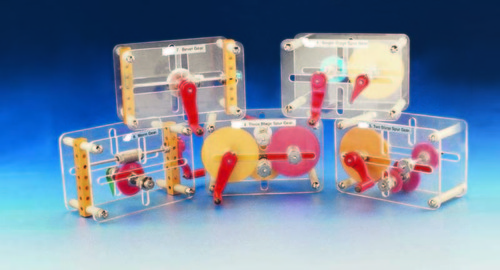

Single Stage Spur Gears

Single Stage Spur Gears with Intermediate

Two Stage Spur Gears

Three Stage Spur Gears

Single Stage Bevel Gears

Single Stage Helical Gears

Single Stage Spiral Gears

Precision Engineering & Durability

SG Series Spur Gears are crafted to deliver outstanding reliability, enhanced precision, and superior strength. Each gear undergoes rigorous processes to ensure minimal backlash, extending lifespan and operational consistency even in demanding industrial environments.

Customizable for Versatile Applications

With a range of teeth counts, modules, and mounting types, these gears can be tailored to suit the specific requirements of automation lines, conveyor systems, and gearboxes. Custom finishes and surface treatments further adapt the product for unique operational needs.

FAQs of Spur Gears:

Q: How are the SG Series spur gears manufactured to ensure minimal backlash and high precision?

A: SG Series spur gears are produced under strict ISO, AGMA, and DIN standards using advanced machining and precision grinding techniques. This process guarantees tight tolerances, minimal backlash, and accuracy levels from DIN 8 to DIN 6, ensuring reliable and quiet operation.Q: What materials are used for these spur gears, and how do they benefit industrial applications?

A: Our gears are made from alloy steel, cast iron, carbon steel, and stainless steel. These materials provide high strength, excellent wear resistance, and corrosion protection, making them ideal for heavy-duty industrial machinery, automation processes, and conveyor systems.Q: Where can SG Series spur gears be installed?

A: These gears are suitable for use in industrial equipment such as gearboxes, automation machinery, conveyor lines, and other mechanical drive systems. Their versatile mounting types, including bored, keyway, and customized options, facilitate easy integration into various setups.Q: What surface treatments are available, and what advantages do they offer?

A: SG Series spur gears can be ordered with hardened, ground, and black oxide coated surfaces. These treatments enhance wear resistance, reduce friction, and offer improved corrosion protection, further extending the gears operational life.Q: When should a custom gear design be considered?

A: Custom gear designs are recommended when specific requirements for tooth count, module size, mounting type, or surface finish are needed to match unique machinery or operational conditions. Our team provides consultation to deliver tailored solutions for specialized applications.Q: How does the gears capacity and size accommodate different torque and dimensional needs?

A: With torque transmission capacities up to 2000 Nm and diameter options from 50 mm to 600 mm, the SG Series gears cover a broad range of industrial needs. Weight varies accordingly, allowing selection based on exact mechanical and power requirements.Q: What are the key benefits of choosing SG Series spur gears for automation and conveyor systems?

A: Clients select SG Series gears for their precision engineering, low noise, high durability, and customizable features. These advantages translate to smoother operation, reduced maintenance, and reliable performance in automated and conveyor-driven environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Self Recording Rain Gauge

Type : Rain Gauge

Equipment Materials : Metal and Plastic

Feature : Self Recording Weatherproof

Automation Grade : Automatic

Usage : Hydrology Meteorology

Core Components : Sensor Recording Drum

Reynold's Apparatus

Type : Fluid Mechanics Apparatus

Equipment Materials : Stainless Steel Plastic

Feature : Used for determining the Reynolds number in fluid flow

Automation Grade : Manual

Usage : Laboratory

Core Components : Water Pump Transparent Tubes Flow Tank

Alum Jar Test Apparatus Electrically Operated

Type : Jar Test Apparatus

Equipment Materials : Metal and Glass

Feature : Uniform heating and paddling

Automation Grade : Electrically Operated

Usage : Water treatment and coagulation testing

Core Components : Heating Element Rotating Paddles

De-Lavel Turbine

Type : Steam Turbine

Equipment Materials : Metal

Feature : Steampowered conversion device

Automation Grade : Manual

Usage : Mechanical energy generation

Core Components : Turbine wheel nozzle

GST : 06ACOPS0805K1ZD

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry