SINGLE STAGE QUARTZ DISTILLATION

SINGLE STAGE QUARTZ DISTILLATION Specification

- Frequency

- 50 Hz

- Model No

- STD-Q1

- Power Source

- Electric

- Temperature Range

- Upto 400C

- Feature

- Highly Efficient

- Capacity

- 1.5 Ltr/hr

- Voltage

- 220240 V AC

- Measurement Range

- Distillate Output 1.5 Ltr/hr

- Accuracy

- 100 %

- Automation Grade

- Semi-Automatic

- Core Components

- Quartz Heater, Cooling Coil, Heater Housing, Water Level Sensor

- Equipment Materials

- Quartz (Body), Borosilicate Glass (Condensing Parts)

- Type

- Single Stage Distillation Unit

- Usage

- Laboratory

- Dimension (L*W*H)

- 450 mm x 200 mm x 400 mm

- Weight

- Approx. 8 kg

- Cooling Water Requirement

- 1 Ltr/min

- Safety

- Fully Enclosed System for Operator Safety

- Cleaning

- Easy-to-Clean Construction

- Heating Element Material

- Quartz

- Protection

- Low Water Cut-off and Overheat Protection

- Distillate Quality

- Pyrogen-free, Particle-free

- Power Consumption

- 1.5 KW

- Output Water Conductivity

- 1.52.0 S/cm

- Operating Pressure

- Atmospheric

- Installation Type

- Bench-top

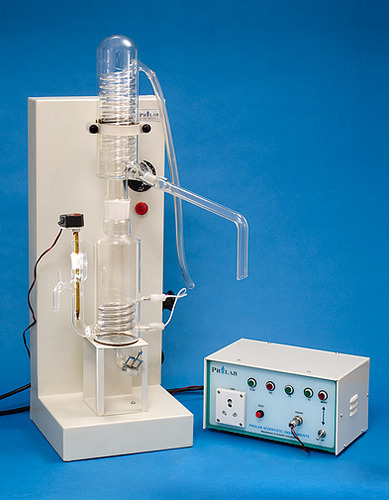

About SINGLE STAGE QUARTZ DISTILLATION

SINGLE STAGE QUARTZ DISTILLATION

The apparatus consists of a boiler made from high purity quartz with built in heater and bottom discharge joint for easy cleaning of deposits. A spiral condenser is fitted on the boiler with receiving adapter. The unit comes with Safety Control Unit (Optional) to protect the Glass parts in case of water failure or overheating.

Quartz can withstand very high temperature variation, thus it is thermal shock proof.

| Conductivity | 1.0 - 1.5 S/cm with Borosilicate Condenser |

| 0.5 0.8 S/cm with Quartz Condenser | |

| Distilled Water Quality | Pyrogen Free |

| pH | 5.5 6.0 |

| Distillate Temperature | 50-60C |

**All the parameters are under Standard Test Conditions.

Advantages

Rust proof sturdy aluminum stand as base.

Replaceable clamps are provided for better adjustment and alignment of the boiler and condenser.

Advanced Features

Distillate is pyrogen free; also it is free of heavy metals.

Switch on time is less than minute providing distilled water instantly.

Low maintenance is required.

Borosilicate Condenser

| | | | | |

| Output Cap. (Approx.) | 2 ltr/hr | 5 ltr/hr | 8 ltr/hr | 10 ltr/hr |

| Power Rating (Total) | 1.7 Kw | 4.4 Kw | 6 Kw | 9 Kw |

| Cooling Water Consumption (Approx.) | 35 ltr/hr | 65 ltr/hr | 90 ltr/hr | 120 ltr/hr |

Quartz Condenser

| | | | | |

| Output Cap. (Approx.) | 2 ltr/hr | 5 ltr/hr | 8 ltr/hr | 10 ltr/hr |

| Power Rating (Total) | 1.7 Kw | 4.4 Kw | 6 Kw | 9 Kw |

| Cooling Water Consumption (Approx.) | 35 ltr/hr | 65ltr/hr | 90ltr/hr | 120ltr/hr |

Quartz Boiler for 2 ltr/hr Distillation

Quartz Boiler for 5 ltr/hr Distillation

Quartz Boiler for 8 ltr/hr Distillation

Quartz Boiler for 10 ltr/hr Distillation

Borosilicate coil condenser for 2 ltr/hr Distillation

Borosilicate coil condenser for 5 ltr/hr Distillation

Borosilicate coil condenser for 8 ltr/hr Distillation

Borosilicate coil condenser for 10 ltr/hr Distillation

Quartz coil condenser for 2 ltr/hr Distillation

Quartz coil condenser for 5 ltr/hr Distillation

Quartz coil condenser for 8 ltr/hr Distillation

Quartz coil condenser for 10 ltr/hr Distillation

Safety Cut-Off Device

Safety Cut-Off Device

Highly Pure Water for Laboratory Needs

This single stage quartz distillation unit is engineered to produce distillate that is both pyrogen-free and particle-free, making it ideal for analytical, biological, and pharmaceutical laboratory applications. With output water conductivity maintained at 1.52.0 S/cm, you can trust its performance for sensitive experimental protocols, ensuring high-quality results every time.

Safe and Efficient Operation

Equipped with quartz heating elements and multiple safety features including low water cut-off, overheat protection, and a fully enclosed system, this distillation unit prioritizes operator safety and equipment longevity. Its semi-automatic operation and atmospheric pressure design ensure convenient and efficient use in laboratory settings without compromising on quality.

FAQs of SINGLE STAGE QUARTZ DISTILLATION:

Q: How does the Single Stage Quartz Distillation process work?

A: The unit operates by heating water using a high-purity quartz element. As water vaporizes, it travels through borosilicate glass condensing parts, cooling into distilled water that is collected. This process effectively removes contaminants, yielding pyrogen-free and particle-free distillate.Q: What are the main benefits of using this quartz distillation unit?

A: The main advantages include the production of highly pure, laboratory-grade water with very low conductivity, efficient semi-automatic operation, and robust safety features. Its easy-to-clean quartz and glass construction reduces maintenance, while reliable safety cut-offs and a fully enclosed system protect both users and the unit.Q: When should the quartz distillation unit be cleaned and how is this done?

A: Regular cleaning is recommended based on usage frequency and feed water quality. The easy-to-clean construction allows users to access and rinse inner components, preventing scaling or residue buildup. Follow the manufacturers manual for safe and thorough cleaning procedures.Q: Where can this distillation unit be installed in a laboratory?

A: This product is designed for bench-top installation, fitting easily onto standard laboratory work surfaces due to its compact dimensions (450 mm x 200 mm x 400 mm) and light weight (approx. 8 kg). Ensure proximity to a cooling water supply and power source for optimal operation.Q: What makes the distillate from this unit suitable for critical laboratory procedures?

A: Distilled water produced by this unit is both pyrogen-free and particle-free, with conductivity between 1.52.0 S/cm, ensuring it does not interfere with sensitive assays or experiments. The construction materials (quartz and borosilicate) further help maintain purity by preventing leaching or contamination.Q: How much water can the unit produce per hour and what are the cooling requirements?

A: The distillation unit has a capacity of 1.5 liters per hour. It requires a cooling water supply of approximately 1 liter per minute to efficiently condense vaporized water back into a liquid state and maintain consistent operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in WATER DISTILLATION UNITS Category

WATER RO (REVERSE OSMOSIS SYSTEM)

Automation Grade : SemiAutomatic

Core Components : RO Membrane Filter Cartridges Pump

Voltage : 220V AC

Equipment Materials : ABS Plastic

Accuracy : High

Dimension (L*W*H) : 300x200x400 mm

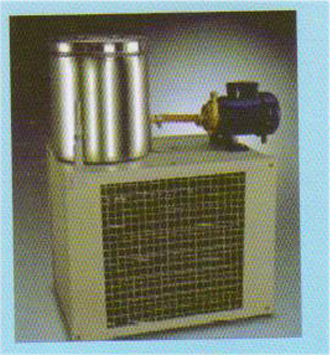

WATER CIRCULATOR / CHILLER UNIT FOR WATER DISTILLATIONS AND STILLS

Automation Grade : SemiAutomatic

Core Components : Compressor Heat Exchanger Pump

Voltage : 220V AC

Equipment Materials : Stainless Steel

Accuracy : 0.1C

Dimension (L*W*H) : 600 x 300 x 400 mm

ALL QUARTZ DOUBLE DISTILLATION

Automation Grade : SemiAutomatic

Core Components : Quartz Heater, Boiler

Voltage : 220240 V

Equipment Materials : Quartz

Accuracy : 100 %

Dimension (L*W*H) : Not Available

WATER STILL WITH SHEATHED SILICA HEATER

Automation Grade : Manual

Core Components : Borosilicate Glass Boiler, Condenser, Sheathed Silica Heater

Voltage : 220240 V AC

Equipment Materials : Borosilicate Glass; Heater Sheath Silica

Accuracy : 100 %

Dimension (L*W*H) : Approx. 470 x 190 x 360 mm

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry