Inter Connected Gears

Inter Connected Gears Specification

- Accuracy

- High precision

- Power Source

- Mechanically driven

- Core Components

- Gear Teeth, Shafts, Bushings

- Type

- Inter Connected Gears

- Usage

- Mechanical transmission, power transfer, industrial machines

- Capacity

- Customizable as per application

- Dimension (L*W*H)

- As per design specifications

- Weight

- Varies with size and configuration

About Inter Connected Gears

Advanced Features and Industry Applications

Inter Connected Gears elevate your mechanical systems with custom-tooth modules, high torque capacity, and low operational noiseensuring crowning performance in even the most demanding conditions. Used extensively in industrial machines, these gears are trusted by manufacturers and suppliers requiring robust power transfer and enviable precision. Enjoy application-specific customization in dimensions and speed ratio, making them suitable for a variety of mechanical transmission tasks across Indias industrial sector.

FOB Port, Delivery Assurance, and Product Certifications

Our Inter Connected Gears are supplied from major FOB ports in India, offering prompt delivery times based on your proposal amount and project scale. Rate quotes are available upon request. Each product comes with certifications attesting to qualityensuring trust and reliability. We streamline supply to meet industrial standards, guaranteeing that every gear meets or exceeds compliance for performance and safety in your application.

FAQs of Inter Connected Gears:

Q: How are the specifications of Inter Connected Gears customized for different applications?

A: Our Inter Connected Gears can be tailored in terms of teeth module, torque capacity, speed ratio, and dimensions as per the customers distinct industrial requirements. This flexibility ensures optimal performance across a wide range of machinery.Q: What is the process for selecting and ordering Inter Connected Gears?

A: Begin by providing your technical requirements, such as torque, size, and operational environment. We evaluate your needs, offer a proposal amount, and supply a product that meets your exact specifications, supported by timely delivery and certification.Q: When is periodic maintenance necessary for these gears?

A: Periodic lubrication is recommended to ensure long-term reliability. The maintenance interval depends on operational intensity and environmental conditions, but regular checks safeguard optimal performance and extended service life.Q: Where are these Inter Connected Gears typically used?

A: They are primarily installed in industrial environmentssuch as manufacturing plants, processing facilities, and mechanical transmission systemswhere robust and efficient power transfer is crucial.Q: What benefits do Inter Connected Gears offer compared to standard gears?

A: They provide enviable precision, higher torque capacity, customizable configurations, and a hardened surface for durabilityresulting in low noise operation and reliable functionality with minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

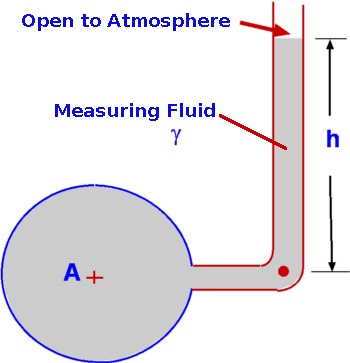

Piezometer Tube

Usage : Fluid pressure measurement in laboratories industries

Feature : Measures fluid pressure using height difference in tube column

Type : Piezometer tube

Automation Grade : Manual

Core Components : Measuring tube fluid () pressure chamber (A+)

Equipment Materials : Transparent tube durable pressure chamber material

Ignition System Of An Automobile

Usage : Automobile Engine Ignition

Feature : Efficient Ignition System

Type : Automobile Ignition System

Automation Grade : Manual

Core Components : Induction Coil Regulator Spark Plug Motor

Equipment Materials : Metal Plastic

Recording Link

Usage : Temperature and humidity recording

Feature : Continuous Recording, Manual Operation

Type : Recording Link

Automation Grade : Manual

Core Components : Recording Drum, Pointer, Chart Paper, Housing

Equipment Materials : Stainless Steel, Glass

Proving Ring Peneetrometer

Usage : Soil Testing

Feature : Designed for soil penetration testing

Type : Proving Ring Penetrometer

Automation Grade : Manual

Core Components : Ring Dial Indicator Handle

Equipment Materials : Steel

GST : 06ACOPS0805K1ZD

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry