Centrifugal Track (Loop)

Centrifugal Track (Loop) Specification

- Temperature Range

- -10C to 80C

- Automation Grade

- Semi-Automatic

- Power Source

- Electric

- Core Components

- Precision Motor, Performance Sensors

- Feature

- Highly Efficient

- Capacity

- Not Specified

- Voltage

- 230 V

- Measurement Range

- 0.1 g to 500 g

- Model No

- CTL-100

- Frequency

- 50 Hz

- Accuracy

- 100 %

- Equipment Materials

- Stainless Steel, Aluminium

- Type

- Centrifugal Track (Loop)

- Usage

- Laboratory

- Display Type

- Digital

- Dimension (L*W*H)

- 120 cm x 45 cm x 95 cm

- Weight

- 35 kg

- Safety System

- Emergency Stop Button

- Mounting Type

- Floor-standing

- Protection Level

- IP 54

- Additional Product Specifications

- Control System

- Microcontroller Based

- Finish

- Corrosion Resistant Coating

- Track Design

- Enclosed Loop Shape

- Rotation Speed

- Adjustable up to 4500 rpm

- Noise Level

- < 60 dB

- Cooling System

- Integrated Fan

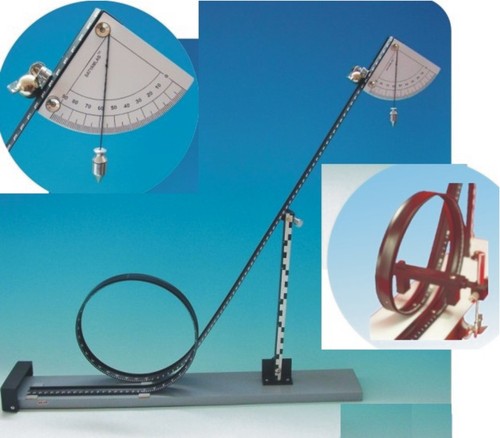

About Centrifugal Track (Loop)

Centrifugal Track (Loop)

For determination of minimum velocity at the upper point of the circular loop and to study the total energy along the track from the start point to the end point using photogates & Digital Timer. By using balls of different masses, the transformation potential energy into kinetic energy and vice versa, and the independence of velocity of descent on mass of the ball can be demonstrated. Consists of aluminium track with circular loop of diameter about 20cm, mounted on a base with leveling screws and air-level. The complete track is electrostatically black painted with millimeter ruler from the top to the lowest point of the loop and has continuously adjustable angle of inclination which can be read directly from the goniometric scale 0-90 graduated in degree using plumb line. Releasing attachment is provided for holding and releasing the ball at the upper point. A box at the end of the track catches the steel ball. Includes 2 pairs of spheres of different material and different diameters (one pair rubberized stainless steel, one pair rubber).

Advanced Loop Track Design

The Centrifugal Track (Loop) stands out with its enclosed loop configuration, providing continuous, uniform operation and high safety standards. This design minimizes contamination risk and enhances sample security during high-speed testing. Its corrosion-resistant materials ensure durability, especially in rigorous laboratory environments, while the floor-standing build promotes stability and ease of integration.

Precision and Efficiency in Laboratory Applications

Equipped with a microcontroller-based digital control system, this unit offers precise speed adjustments up to 4500 rpm, ensuring dependable performance for sample analysis. Its advanced sensors and emergency stop button maximize user safety and operational control. With 100%% accuracy and a broad measurement range, the CTL-100 is versatile, accommodating a variety of lab processes efficiently.

Optimized for Safety and Comfort

Operating at noise levels below 60 dB, the Centrifugal Track (Loop) prioritizes a quieter laboratory environment. Its integrated fan effectively manages internal temperatures, maintaining operational consistency from -10C to 80C. The IP54 protection level further safeguards the unit from dust and splashes, making it a robust choice for laboratory professionals.

FAQs of Centrifugal Track (Loop):

Q: How is the rotation speed of the Centrifugal Track (Loop) adjusted?

A: The Centrifugal Track (Loop) utilizes a microcontroller-based control system with a digital display, allowing precise adjustment of rotation speed up to 4500 rpm. Operators can easily set and monitor the speed for optimal experimental requirements.Q: What safety features are incorporated in the CTL-100 model?

A: For enhanced laboratory safety, the CTL-100 is equipped with an emergency stop button, an enclosed loop design, and integrated performance sensors. These features ensure user protection during operation and allow rapid response in case of unexpected events.Q: When should the Centrifugal Track (Loop) be used?

A: The Centrifugal Track (Loop) is ideal for laboratory applications requiring high-precision, high-speed rotation, such as separation processes, sample mixing, and various analytical tasks. Its wide temperature and measurement range enhance its suitability for diverse research settings.Q: Where is the Centrifugal Track (Loop) best installed?

A: Designed as a floor-standing unit, the CTL-100 should be placed on a stable, flat laboratory floor with accessible power supply (230 V, 50 Hz) and sufficient ventilation for the integrated fan system. Its IP54 protection makes it suitable for general laboratory environments.Q: What are the main benefits of using the Centrifugal Track (Loop) in the lab?

A: Key benefits include outstanding measurement accuracy (100%%), minimal noise pollution (<60 dB), robust construction with corrosion-resistant coating, and reliable safety features. These advantages collectively enhance productivity and user confidence in high-stakes laboratory work.Q: How does the integrated fan cooling system benefit the equipment?

A: The integrated fan cooling keeps the internal components at optimal temperatures, especially during extended usage or high-speed operation, thus ensuring consistent performance, preventing overheating, and prolonging equipment lifespan.Q: What materials are used in the construction of the Centrifugal Track (Loop)?

A: The unit is primarily constructed from stainless steel and aluminium, combining durability with resistance to laboratory chemicals and corrosion, and ensuring long-term reliability in laboratory conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PHYSICS LABORATORY EQUIPMENT Category

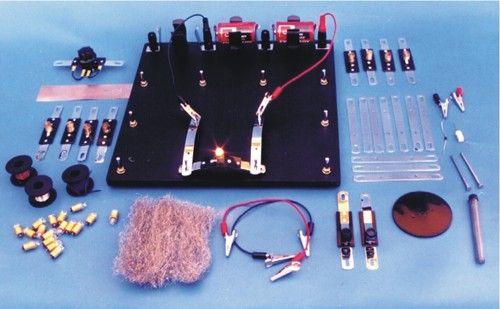

Worcester Circuit Board kit

Core Components : Microprocessor, Capacitors, Resistors, Integrated Circuits

Feature : Highly Efficient

Automation Grade : Manual

Type : Circuit Board Kit

Power Source : Electric

Capacity : Not Specified

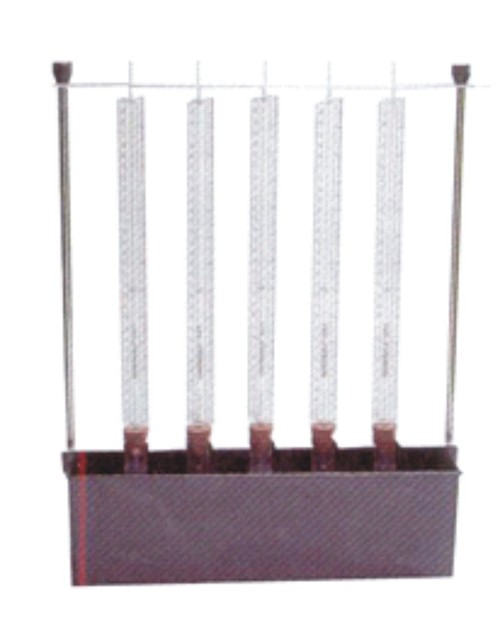

DIFFERENT EXPANSION OF LIQUIDS

Core Components : Glass Tubes Metal Framework Liquid Container

Feature : Measures expansion of liquids

Automation Grade : Manual

Type : Laboratory Equipment

Power Source : None

Capacity : 5 Measurements

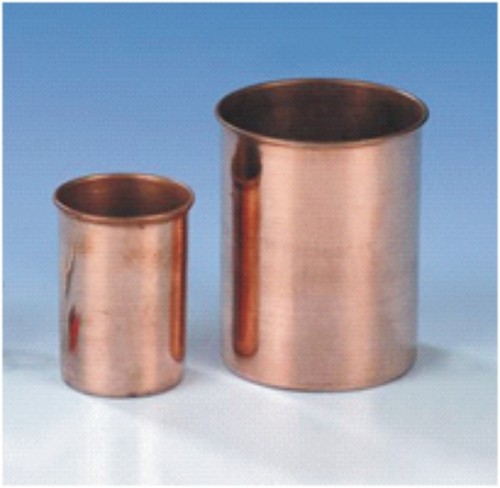

CALORIMETER

Core Components : Copper

Feature : Durable and efficient

Automation Grade : Manual

Type : Bomb Calorimeter

Power Source : Manual

Capacity : 2 liters

FREE-FALL TUBE

Core Components : Glass Tube, Stand, Scale Markings

Feature : Transparent construction, Chemical resistant, Easy to clean

Automation Grade : Manual

Type : Laboratory Testing Equipment

Power Source : Not required (manual operation)

Capacity : 100 ml

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry