AC Stirrers / Emulsifiers & Homogenizers

AC Stirrers / Emulsifiers & Homogenizers Specification

- Power Source

- Electric

- Core Components

- AC Motor, Stirring Shaft, Homogenizing Head

- Frequency

- 50 Hz

- Automation Grade

- Semi-Automatic

- Voltage

- 220V

- Accuracy

- 100 %

- Measurement Range

- 50 ml to 2000 ml

- Temperature Range

- Up to 100C

- Capacity

- 2 Liters

- Model No

- ACM-02

- Feature

- Highly Efficient

- Equipment Materials

- Stainless Steel, PTFE

- Type

- Stirrers / Emulsifiers & Homogenizers

- Usage

- Laboratory

- Display Type

- Digital

- Dimension (L*W*H)

- 400 x 220 x 300 mm

- Weight

- 8 kg

About AC Stirrers / Emulsifiers & Homogenizers

AC Stirrers These Stirrers are specially designed brushless AC variable speed stirrers driven by frequency inverter to ensure reproducible speed with any load. Model RQ-140/D-FP is with flame proof motor & frequency inverter inside flameproof enclosure, suitable for use in Group II A & II B hazardous areas. These stirrers have steady & constant speed for viscous materials and solutions that change viscosity during mixing. It has built in digital RPM indicator for process validation and reproducibility. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Salient Features: RQ-127A/D suitable for homogenizing of tissues at high speed available. Chuck to hold shaft upto 10 mm dia. fitted with Ptfe grinding pestle. 50 ml. Glass homogenising cup with rod supplied as standard, optional available 5 ml, 15 ml, 25 ml. & 100 ml. RQ-127/D, RQ-130/D, RQ-130B/D are with AC/DC motor, these units are 3 bladed impeller (optional Saw Cutter) housed in flange type cage.Optional digital speed indicator for precise setting of speed. RQ-140/DE specially designed brushless AC variable speed Emulsifier driven by frequency inverter to ensure reproducible speed with any load. Steady & constant speed ideal for solutions that change viscosity during mixing. Emulsifier has built in digital RPM indicator for process validation and reproducibility. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Homogenizing and Stirring

The ACM-02 features a powerful AC induction motor and a variable speed control, enabling precise adjustment from 200 to 3000 RPM. This versatility meets diverse laboratory requirements, from gentle stirring to vigorous emulsifying, ensuring consistent and accurate sample processing within a measurement range from 50 ml to 2 liters.

Robust and Safe Performance

With built-in overload protection and a safety-focused design (IP 21 rating), the ACM-02 assures laboratory personnel of dependable operation. The stainless steel 304 blade resists corrosion, while a digital display provides real-time speed and temperature readings, enhancing user control and process accuracy.

FAQs of AC Stirrers / Emulsifiers & Homogenizers:

Q: How do I operate the ACM-02 Stirrers / Emulsifiers & Homogenizer safely in the laboratory?

A: To operate the ACM-02 safely, ensure the unit is placed on a stable surface, connect to a mains voltage of 220V, and use the digital interface to set desired speed and temperature. The overload protection feature automatically prevents damage from excessive loads. Maintain operating humidity between 10%% and 80%% RH for optimal performance.Q: What laboratory processes are suitable for this homogenizers speed and capacity range?

A: The ACM-02 is ideal for emulsification, dispersion, and homogenization tasks for chemical, biological, and pharmaceutical samples. Its 2003000 RPM speed range and 0.22 liter homogenizing capacity cover common laboratory-scale processing, including sample preparation, mixing reagents, and cell disruption.Q: When should I adjust the variable speed control on the ACM-02?

A: Adjust the variable speed control during sample preparation to match the viscosity and type of material being processed. Higher speeds (up to 3000 RPM) suit homogenizing tougher samples, while lower speeds are preferable for gentle mixing and heat-sensitive substances.Q: Where is the best place to use and install this equipment in a laboratory?

A: The ACM-02 should be installed within a clean, dry workspace that is properly ventilated and isolated from direct liquid contact. Its compact size (400 x 220 x 300 mm) allows for convenient placement on benchtops near other essential laboratory instruments.Q: What benefits does the stainless steel 304 blade provide during emulsification?

A: The stainless steel 304 blade ensures resistance to corrosion and enhances durability under continuous laboratory use. This material also guarantees hygienic processing, maintaining sample integrity throughout emulsification, homogenization, and stirring tasks.Q: How does the overload protection feature enhance safety when using the ACM-02?

A: Overload protection automatically shuts down the motor if excessive load or abnormal operation is detected, safeguarding both the equipment and user. This helps prevent accidents, equipment damage, and ensures steady operational efficiency.Q: What is the process for cleaning and maintaining this emulsifier/homogenizer?

A: After use, disconnect the ACM-02 from power, disassemble core components like the blade and shaft, then clean them with non-abrasive, laboratory-grade cleaners. Ensure all components are thoroughly rinsed and dried before reassembly. Regular inspection of the AC motor and digital controls assures longevity and consistent accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CENTRIFUGES & LABORATORY STIRRERS Category

R- 8C & R- 8C DX

Measurement Range : Not Specified

Dimension (L*W*H) : 325 x 230 x 260 mm

Usage : Laboratory

Temperature Range : Up to 100C

Weight : 6.5 kg

Capacity : 8 Tubes

Direct Drive Stirrers

Measurement Range : 02 Liters

Dimension (L*W*H) : 300 mm x 225 mm x 425 mm

Usage : Laboratory

Temperature Range : Ambient to 100C

Weight : 8 kg

Capacity : 2 Liters

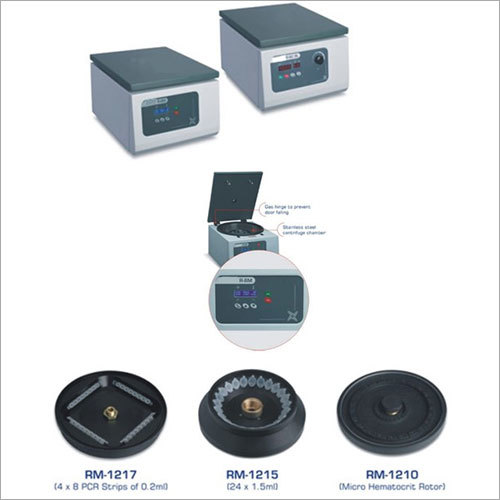

Laboratory Centrifuges

Measurement Range : Up to 4000 rpm

Dimension (L*W*H) : 325 x 340 x 295 mm

Usage : Laboratory

Temperature Range : Ambient to 80C

Weight : 810 kg

Capacity : 12 Tubes

Magnetic Stirrers

Measurement Range : 0 to 1200 RPM

Dimension (L*W*H) : 230 x 180 x 120 mm

Usage : Laboratory

Temperature Range : Up to 340C

Weight : 3.5 kg

Capacity : 2 Liters

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry