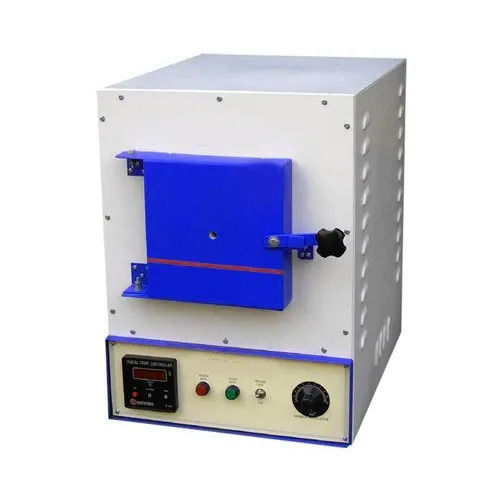

MUFFLE FURNACE

MUFFLE FURNACE Specification

- Automation Grade

- Semi Automatic

- Feature

- Rapid Heating, High Accuracy Temperature Control

- Temperature Range

- Up to 1200C

- Accuracy

- 1C

- Model No

- MF-1200

- Power Source

- Electric

- Measurement Range

- Ambient to 1200C

- Capacity

- 2 Kg

- Voltage

- 220-240 V AC

- Core Components

- Heating Element, Digital Controller

- Frequency

- 50 Hz

- Equipment Materials

- Mild Steel Outer, Ceramic Chamber

- Type

- Lab Furnace

- Usage

- Laboratory, Heat Treatment

- Display Type

- Digital

- Dimension (L*W*H)

- 21 x 14 x 16

- Weight

- Approx 45 kg

About MUFFLE FURNACE

Industrial Furnace Grooved Type Working temperature is 1000 inside chamber is made of grooved refractory for supporting the heating elements on all four sides. Outer body is made of thick mild steel sheet, painted in attractive stoved enamel paint. Heating element made of wire which is easily replaceable. Complete with energy regulator, pyrometer, indicator, thermocouple and copper thermal fuse. Model No. SSI/89

|

|

Advanced Heating Technology

Powered by Kanthal A1 heating elements and a digital PID controller, this muffle furnace ensures rapid and even heating with high thermal stability. The chambers ceramic fiber construction and thick insulation minimize heat loss, resulting in efficient operation and consistent results for your laboratory needs.

User-Friendly and Safe Operations

The furnace features a sturdy front-opening insulated door with a safety door interlock to prevent accidental exposure to high temperatures. The digital display and controls make programming simple, while built-in over-temperature protection maintains safe conditions during extended use. An optional observation window allows users to monitor samples safely.

Versatile Laboratory Applications

Designed for laboratories, this furnace supports a range of processes including material testing, ashing, heat treatment, and thermal analysis. Accommodating up to 2 kg and offering a wide temperature range (ambient to 1200C), it is suitable for research, quality control, and routine laboratory procedures.

FAQs of MUFFLE FURNACE:

Q: How does the MUFFLE FURNACE achieve rapid heating and precise temperature control?

A: The MUFFLE FURNACE utilizes Kanthal A1 heating elements and a digital PID controller, enabling it to reach 1100C in 20 minutes and maintain a consistent temperature to within 1C for reliable results.Q: What safety features are included in this furnace?

A: It is equipped with a door interlock to prevent opening at high temperatures and an over-temperature protection system to automatically regulate heat levels, ensuring safe operation for users.Q: When should I use the observation window feature?

A: Choose the observation window (optional) when you need to visually monitor your samples during heating processes without interrupting the furnaces cycle or compromising safety.Q: Where should I install the MUFFLE FURNACE for optimal performance?

A: Install the furnace in an indoor, dust-free, and well-ventilated area to ensure efficient heat dissipation and consistent performance over time.Q: What materials are used in the construction of the chamber and exterior?

A: The chamber is crafted from high-quality ceramic fiber for excellent insulation and temperature stability, while the exterior features a durable mild steel body with a powder-coated finish.Q: How does the furnace benefit laboratory heat treatment processes?

A: It offers rapid, reliable heating, high accuracy, and robust safety features. This enables precise heat treatment, ashing, and thermal analysis, improving workflow efficiency and experiment reproducibility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCIENTIFIC & LABORATORY RESEARCH APPARATUS Category

Chiller Refrigerated Circulater Model No. SSI/71

Usage : Laboratory

Feature : Highly Efficient

Equipment Materials : Corrosion resistant Stainless Steel

Type : Chiller Refrigerated Circulater

Voltage : 220240 V

Frequency : 50 Hz

VACUUM OVEN

Usage : Laboratory

Feature : Highly Efficient

Equipment Materials : Stainless Steel

Type : Vacuum Oven

Voltage : 220 V

Frequency : 50 Hz

B.o.d. Incubator

Usage : Laboratory

Feature : Highly Efficient

Equipment Materials : Stainless Steel Inner Chamber, Powder Coated Outer Body

Type : B.O.D. Incubator

Voltage : 220 V AC

Frequency : 50 Hz

Rotary Vacuum Evaporator Diagonal Condenser Model No. SSI/62

Usage : Laboratory

Feature : Highly Efficient

Equipment Materials : Borosilicate Glass and Stainless Steel

Type : Rotary Vacuum Evaporator

Voltage : 220240 V

Frequency : 50 Hz

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry