Bed Material Sampler

Bed Material Sampler Specification

- Power Source

- Manual

- Capacity

- 250 ml sample per operation

- Feature

- High heat resistance, durable design, easy operation

- Core Components

- Sampling tube, handle, collecting chamber

- Measurement Range

- Typically 100250 ml per sample

- Accuracy

- 5% of sample volume

- Automation Grade

- Manual

- Temperature Range

- Up to 1000C

- Equipment Materials

- Stainless Steel construction with heat resistant handle

- Type

- Manual Sampler

- Dimension (L*W*H)

- Approx. 500 mm length x 80 mm width x 60 mm height

- Weight

- Approx. 2.5 kg

- Surface Finish

- Polished stainless steel

- Heat Resistance

- Up to 1100°C

- Sample Collection Method

- Direct dipping and retrieval

- Maintenance

- Minimal, easy to clean

- Handle Type

- Ergonomic insulated grip

- Packaging Type

- Corrugated box with foam padding

- Application

- Used in thermal power plants, cement industries, chemical processing units

- Sampling Depth

- Up to 400 mm

About Bed Material Sampler

Superior Build & Targeted Application

Our Bed Material Sampler features premium stainless steel construction with a heat-resistant, ergonomic handle, crowning it ideal for environments up to 1100C. Designed for direct dipping and retrieval, it ensures stellar accuracy and robust sample collection from operational zones in power, cement, and chemical processing industries. This laureate samplers 250 ml capacity per operation, polished finish, and manual methodology make it a preferred choice for those requiring reliability, durability, and precise results in core sampling tasks.

Trusted Supply Ability & Quick Dispatch

We offer a strong export market presence, with consistent supply ability to meet bulk or repeat orders. Expect prompt arrival with packing & dispatch done in high-grade corrugated boxes padded with foam for ultimate protection. Typical delivery time is streamlined for efficiency, ensuring you receive your bed material sampler swiftly. We accept versatile payment terms, catering to varied procurement policies and facilitating a seamless buying journey from order placement to timely arrival at your doorstep.

FAQs of Bed Material Sampler:

Q: How is the Bed Material Sampler operated during sample collection?

A: The Bed Material Sampler operates manually, using an ergonomic insulated grip for comfortable handling. It is directly dipped into the bed material, allowing efficient sample retrieval even at temperatures up to 1100C.Q: What specific industries can capitalise on the use of this sampler?

A: Industries such as thermal power plants, cement manufacturing, and chemical processing units commonly use this top-rated bed material sampler due to its high durability, heat resistance, and reliable sampling capability.Q: When should I use the Bed Material Sampler in my process?

A: Employ the Bed Material Sampler during routine inspections or whenever precise material analysis is needed in high-temperature processes, ensuring optimal system operation and quality control.Q: Where does the collection take place and what is the typical sample volume?

A: The collection is conducted directly in operational zones within reactors or furnaces. Each operation retrieves approximately 100250 ml, with an accuracy of 5% for sample volume.Q: What are the benefits of the featured construction and heat resistance?

A: The stellar construction from polished stainless steel and heat-resistant components ensures longevity, minimises maintenance, and enables safe sampling at temperatures up to 1100C, making it a reliable laureate in demanding industrial settings.Q: How is the sampler maintained and cleaned after use?

A: The design promotes minimal maintenance and straightforward cleaning, ensuring the equipment is always ready for subsequent use, which significantly reduces downtime and enhances operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

E/M by Thompson Method

Feature : Precise measurement of chargetomass ratio (e/m)

Measurement Range : 0 150 A

Core Components : Magnet Scale Power Supply

Weight : 5.5 kg

Type : Experimental Physics Equipment

Dimension (L*W*H) : 150 mm x 100 mm x 200 mm

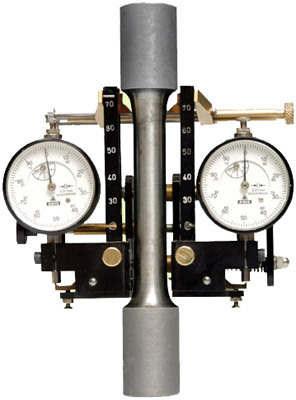

Extensometer

Feature : High accuracy robust design

Measurement Range : 025 mm

Core Components : Steel Aluminum

Weight : 1.5 kg

Type : Mechanical Extensometer

Dimension (L*W*H) : 200 x 100 x 50 mm

Length Comparator :IS:1199-1959:IS:4031-1968

Feature : Length Compatibility Measurement

Measurement Range : 0 300 mm

Core Components : Stainless steel Digital Indicator

Weight : Approx. 5 kg

Type : Length Comparator

Dimension (L*W*H) : Approx. 300 mm x 200 mm x 500 mm

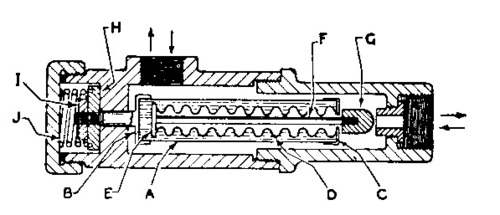

Expansion Steam Trap

Feature : Compact Design, Corrosion Resistant

Measurement Range : Condensate removal in steam applications

Core Components : Thermostatic Capsule

Weight : 320 g

Type : Expansion Steam Trap

Dimension (L*W*H) : 40mm x 80mm x 30mm

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry