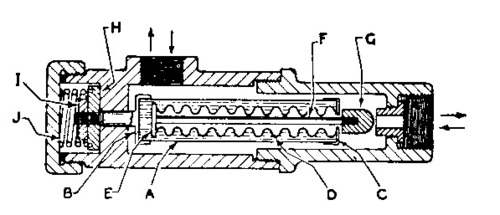

Expansion Steam Trap

Expansion Steam Trap Specification

- Feature

- Compact Design, Corrosion Resistant

- Frequency

- 50 Hz

- Temperature Range

- 0C to 250C

- Core Components

- Thermostatic Capsule

- Accuracy

- 3% at full load

- Measurement Range

- Condensate removal in steam applications

- Capacity

- 0.5 to 10 kg/hr

- Automation Grade

- Automatic

- Equipment Materials

- Forged Brass / Stainless Steel

- Type

- Expansion Steam Trap

- Usage

- Steam Line Condensate Discharge

- Dimension (L*W*H)

- 40mm x 80mm x 30mm

- Weight

- 320 g

- Leakage

- Zero Steam Leakage under normal conditions

- Application

- Industrial, HVAC, Process Plants, Hospitals

- End Connection

- Screwed / Socket Weld

- Body Test Pressure

- 24 bar

- Connection Size

- 15 NB to 25 NB

- Max Discharge Capacity

- 10 kg/hr

- Media

- Steam & Condensate

- Orifice Size

- 1.6 mm

- Installation

- Horizontal or Vertical

- Operating Pressure

- Up to 16 bar

About Expansion Steam Trap

Advantages and Versatile Application of Expansion Steam Trap

The Expansion Steam Trap is designed for precise condensate removal in a wide range of applications beyond conventional steam lines. Its advantage lies in automatic operation and corrosion resistance, streamlining usage in chemical plants, sterilization units, and process heating. Simply install the trap in either a horizontal or vertical orientation for optimal performanceno external power required. Its compact footprint and reliable thermostatic capsule core make it a preferred choice for safe, efficient condensate management.

Certifications, Export Markets, and Supply Details for Expansion Steam Trap

Our Expansion Steam Trap carries standardized certifications for industrial quality, ensuring dependable proposal amounts for bulk purchases. We are a leading manufacturer and supplier with a robust export market across India and beyond. Packing & Dispatch processes are streamlined for prompt delivery. High supply capacity enables us to fulfill large orders efficiently, while careful packaging protects each opulent product during international and domestic transport. Trust us for premium quality and exceptional logistics support.

FAQs of Expansion Steam Trap:

Q: How does the Expansion Steam Trap achieve zero steam leakage under normal conditions?

A: The Expansion Steam Trap utilizes a thermostatic capsule that precisely regulates condensate discharge, ensuring zero steam leakage during standard operation.Q: What materials are used in the construction of the Expansion Steam Trap?

A: This steam trap is manufactured using forged brass or stainless steel, providing superior corrosion resistance and longevity in challenging environments.Q: Where should the Expansion Steam Trap be installed within the system?

A: It is versatile and can be installed in either horizontal or vertical positions, making it suitable for diverse piping layouts in various steam applications.Q: What are the main advantages of using the Expansion Steam Trap in industrial settings?

A: Key advantages include automatic operation, compact design, high accuracy, zero steam leakage, and excellent resistance to corrosion, resulting in reliable and efficient condensate removal.Q: Which process or industries benefit most from the Expansion Steam Traps features?

A: Industries like HVAC, hospitals, process plants, and manufacturing benefit greatly due to the traps precision, robust build, and ability to handle varied condensate loads.Q: When should the Expansion Steam Trap be selected over other types of steam traps?

A: Select this trap when you need precise condensate discharge, corrosion resistance, and flexibility in operating conditions, such as fluctuating temperatures and pressures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Audio Oscillator

Usage : Audio Testing and Calibration

Equipment Materials : Metal and Plastic

Type : Audio Oscillator

Feature : Stable Frequency Output

Core Components : Electronic Circuits

Automation Grade : Manual

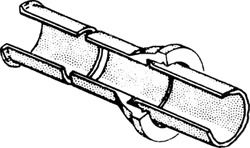

Socket & Spigot Joint

Usage : Water Sewage Gas pipelines

Equipment Materials : PVC Cast Iron Ductile Iron or Steel

Type : Pipe Joint

Feature : Leakproof Durable Joint

Core Components : PVC/HDPE/Metal

Automation Grade : Manual

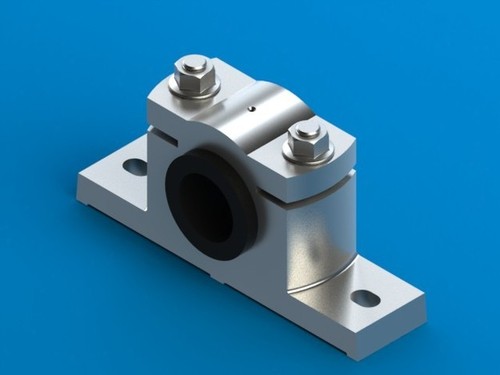

Plummer Block or Pedestal Bearing

Usage : Support for rotating shafts in machinery

Equipment Materials : Cast Iron, Cast Steel (housing); Chrome Steel (bearing insert)

Type : Plummer Block / Pedestal Bearing

Feature : Easy installation/removal, high load capacity, efficient lubrication

Core Components : Housing, Bearing Insert, Cover

Automation Grade : Manual

Demonstration Differential Gear

Usage : Automobile Engineering Models

Equipment Materials : Stainless Steel

Type : Demonstration Differential Gear

Feature : Easy To Install, High Quality

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry