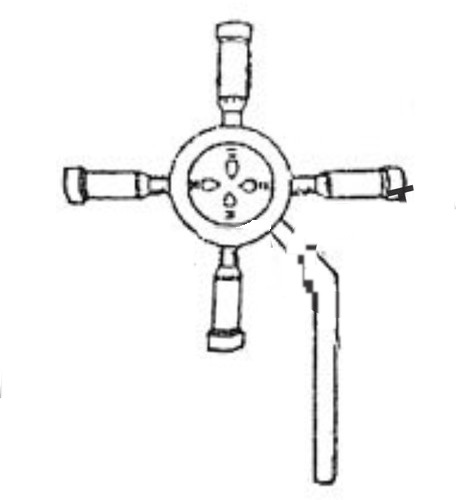

Venturimeters (Cast Iron)

Venturimeters (Cast Iron) Specification

- Automation Grade

- Manual

- Power Source

- Not Required (Mechanical)

- Core Components

- Convergent section, Throat, Divergent section

- Capacity

- Up to 600 m3/hr

- Measurement Range

- 0.2 m3/hr to 600 m3/hr

- Accuracy

- 1% of full scale

- Equipment Materials

- Cast Iron (Body), Brass or Stainless Steel (Throat)

- Type

- Differential Head Flow Meter

- Usage

- Measurement of fluid flow in pipelines

- Dimension (L*W*H)

- Varies with pipe diameter (from 80mm to 600mm bore)

- Weight

- 15 kg to 500 kg (as per model/size)

- Pipe Size Range

- 80mm to 600mm NB

- End Connection

- Flanged pipe ends as per IS/ANSI/DIN standards

- Coating

- Epoxy painted for corrosion resistance

- Max. Working Pressure

- Up to 16 bar

- Testing Pressure

- 24 kg/cm²

- Installation Orientation

- Horizontal/Vertical

About Venturimeters (Cast Iron)

Distinctive Advantages of Cast Iron Venturimeters

Our Venturimeters offer exceptional durability and accuracy, setting them apart as a preferred choice in fluid flow measurement. The primary competitive advantages include corrosion-resistant epoxy coating and compliance with international standards, ensuring longevity and reliability. Their manual operation, high testing pressure, and wide measurement range make them suitable for diverse industrial applications. These features, along with their flexible installation orientation and robust construction, make our Venturimeters a favorable investment among discerning professionals.

Certifications, Export Markets & Valuation of Venturimeters

Supported by prominent industry certifications, our Venturimeters assure supreme quality. With an attractive list price and significant valuation, they offer unmatched value for your expenditure. Products are shipped from Indias main FOB ports, catering to key export markets across Asia, Africa, and the Middle East. These certifications and global reach demonstrate our commitment to stringent quality standards and competitive pricing, elevating customer confidence in every transaction.

FAQs of Venturimeters (Cast Iron):

Q: How do Cast Iron Venturimeters measure fluid flow in pipelines?

A: Cast Iron Venturimeters use the principle of differential head flow. As fluid flows through the convergent, throat, and divergent sections, the change in pressure is measured and correlated to the flow rate, offering high accuracy.Q: What advantages do epoxy-painted Venturimeters provide?

A: Epoxy painting imparts superior corrosion resistance, extending the Venturimeters service life even in harsh environments. This protective coating is especially advantageous for industrial and outdoor applications.Q: Where can these Venturimeters be installed within a piping system?

A: The Venturimeters are versatile in their installation, allowing for both horizontal and vertical placement, accommodating a variety of industrial pipeline layouts and maximizing usability.Q: When should I select a brass throat versus a stainless steel throat?

A: Choose a brass throat for general fluid measurement and a stainless steel throat for applications involving corrosive or high-purity fluids, ensuring optimal performance and longevity.Q: What is the process for verifying Venturimeter accuracy?

A: Accuracy is verified by conducting a pressure test up to 24 kg/cm and ongoing calibration checks to ensure measurement remains within 1% of full scale, as per industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Metacentric Height Apparatus

Equipment Materials : Mild Steel

Feature : For determining Metacentric Height

Core Components : MS Sheet

Usage : Educational Institutions Research Labs

Type : Lab Equipment

Weight : Approx. 510 kg

Parallel Forces Apparatus (Tubular spring balance)

Equipment Materials : Metal and highstrength materials

Feature : Designed to demonstrate the principle of parallel forces

Core Components : Tubular spring balance rod base

Usage : Used for teaching physics concepts related to forces

Type : Educational apparatus

Weight : Lightweight and portable

Abbots Compaction Apparatus

Equipment Materials : Steel

Feature : Compaction testing for cement and soil

Core Components : Metal Frame

Usage : Testing cement and soil compaction

Type : Compaction Apparatus

Weight : Approximately 10 kg

Cylinder Carrier

Equipment Materials : Steel

Feature : Durable Portable EasytoUse

Core Components : Metal Frame Rubber Wheels

Usage : Transporting Gas Cylinders

Type : Cylinder Carrier

Weight : Approximately 15 Kg

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry