Rigidity of Wires

Rigidity of Wires Specification

- Automation Grade

- Manual

- Measurement Range

- Up to 10 mm Deflection

- Core Components

- Wire Clamp, Weights, Rigidity Bar, Indicator Scale

- Power Source

- Not Required (Manual)

- Capacity

- Up to 30 N (Customizable)

- Feature

- Precise Measurement, Stable Base, Corrosion Resistant

- Temperature Range

- Ambient

- Frequency

- Manual Operation

- Accuracy

- 0.01 mm

- Equipment Materials

- Mild Steel Stand, Stainless Steel Wire, Brass Knobs

- Type

- Physical Testing Apparatus

- Display Type

- Dial Indicator with Vernier Scale

- Dimension (L*W*H)

- 350 mm x 120 mm x 200 mm (approx)

- Finish

- Powder Coated

- Wire Diameter Compatibility

- 0.5 mm to 2 mm

- Clamp Material

- Brass with Knurled Finish

- Applications

- Determine Young's modulus by Searles or other Mechanisms

- Packing Type

- Individual Box Packing

About Rigidity of Wires

Reliable Physical Testing for Educational and Industrial Use

The Rigidity of Wires Apparatus is designed for both laboratory and industrial environments. Its physical testing capability supports comprehensive determination of Youngs modulus and wire stiffness, making it an essential tool for academic, research, and quality assurance settings. With customizable force capacities, a stable powder-coated base, and corrosion-resistant brass knurled clamps, users can confidently handle a broad range of wire types within 0.5 mm to 2 mm diameter. Each unit is individually boxed for protection and ease of storage.

Global Delivery, Speedy Order Processing, and Market-Focused Solutions

We prioritize efficient Delivery for every order, shipping from our primary FOB port in India to international destinations. Our streamlined Order Processing system ensures that customers receive their Rigidity of Wires Apparatus promptly, maintaining high Market value in physical testing equipment across main export markets such as Asia, Africa, and Europe. Secure your superior apparatus today to experience rapid fulfillment and reliable after-sales support with every shipment.

FAQs of Rigidity of Wires:

Q: How can the Rigidity of Wires Apparatus be customized for different testing needs?

A: The apparatus offers customizable force capacity up to 30 N, allowing adjustments based on specific material testing requirements, ensuring versatility for both educational and industrial applications.Q: What processes can this apparatus be used for in determining material properties?

A: It is designed primarily to determine Youngs modulus of wires using Searles or similar mechanisms, thanks to precise components like the dial indicator and vernier scale.Q: Where is the main market of export for this apparatus?

A: The Rigidity of Wires Apparatus is chiefly exported to markets in Asia, Africa, and Europe, catering to laboratories, research institutions, and manufacturing units.Q: When should one opt for a manual rather than an automated wire rigidity tester?

A: Manual testers like this apparatus are ideal when detailed, hands-on measurement is required, or in settings where power sources are unavailable or reliability is preferred over automation.Q: What are the benefits of using powder-coated stainless steel and brass in the equipment?

A: Powder-coated finishes provide excellent corrosion resistance and durability, while brass knobs and clamps with knurled finishing ensure secure grip and long-lasting performance.Q: How accurate are the measurements taken with this device?

A: Measurements are highly accurate, offering a precision of 0.01 mm and a deflection measurement range of up to 10 mm, suitable for exacting scientific assessments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Rain Gauge Measuring Jar

Usage : Measuring rainfall levels in meteorological studies

Type : Rain Gauge Measuring Jar

Feature : Weatherresistant construction

Dimension (L*W*H) : Standard dimensions for field applications

Weight : Lightweight portable design

Equipment Materials : Durable materials like plastic or metal for outdoor use

Robinson's Cup Anemometer(with recording counter)

Usage : Wind speed measurement

Type : Cup Anemometer

Feature : Measures total wind run; Cumulative wind speed readout

Dimension (L*W*H) : Approx. 25 cm height, 14 cm cup diameter

Weight : Approx. 800g (anemometer unit)

Equipment Materials : Aluminum alloy; Stainless steel shaft

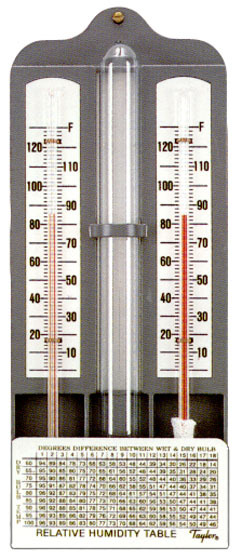

Wet & Dry Bulb Hydrometer

Usage : Relative Humidity Measurement

Type : Wet & Dry Bulb Hydrometer

Feature : Measures Wet & Dry Bulb Temperature

Dimension (L*W*H) : Approximately 10 x 5 x 2 inches

Weight : Approximately 200 grams

Equipment Materials : Plastic Glass

FET Multimeter

Usage : Electrical Measurement (Voltage, Current, Resistance)

Type : FET Multimeter

Feature : High Input Impedance, Battery Test Function, Durable Casing, Portable

Dimension (L*W*H) : 185mm x 95mm x 35mm

Weight : Approx. 400g

Equipment Materials : High Grade Plastic, Metal (Probes)

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry