Reversing Gears

Reversing Gears Specification

- Temperature Range

- Up to 80C

- Capacity

- Custom/Standard Available

- Automation Grade

- Manual

- Frequency

- 50 Hz

- Power Source

- Mechanical

- Core Components

- Gear, Shaft, Housing

- Accuracy

- 0.5 mm

- Feature

- High Efficiency, Smooth Operation

- Equipment Materials

- High Grade Alloy Steel

- Type

- Mechanical Reversing Gear

- Usage

- Marine, Industrial Machinery, Automotive

- Dimension (L*W*H)

- 320 mm x 190 mm x 110 mm

- Weight

- Approx. 32 kg

- Gear Ratio

- 2:1

- Lubrication

- Oil Immersed

- Maximum Input Speed

- 1800 RPM

- Operating Environment

- Indoor/Outdoor

- Service Life

- >25,000 hours

- Maintenance

- Minimal

- Noise Level

- Low

- Design

- Compact and Rigid

- Finish

- Corrosion Resistant Coating

- Mounting Type

- Horizontal

- Safety Features

- Overload Protection

- Shock Resistance

- High

About Reversing Gears

Versatile Applications & Premium Usage

Reversing Gears are engineered to excel in marine, industrial machinery, and automotive uses. Their compact, rigid design, high-grade alloy steel construction, and corrosion-resistant finish empower robust indoor and outdoor performance. The gears offer smooth, accurate operation and are manually operated, making them ideal for environments requiring minimal maintenance and high reliability. Standard and custom capacities are available, providing optimal flexibility for various lifting, transmission, and propulsion needs across industries.

Efficient Delivery and Convenient Supply

Reversing Gears are promptly dispatched to customers, ensuring timely drop-off and safe arrival at designated locations. With supply ability tailored to meet recurring industrial demands, every order is handled with precision to guarantee minimal delivery intervals. Flexible payment terms cater to customer convenience, streamlining transactions for manufacturers, suppliers, and traders. Whether ordering for marine, industrial, or automotive applications, expect seamless order processing from selection to final delivery across India.

FAQs of Reversing Gears:

Q: How is the Reversing Gear installed and what mounting type does it require?

A: The Reversing Gear features a horizontal mounting type, making installation straightforward on compatible machinery. Detailed instructions are provided with each product to ensure precise fitting and optimal alignment.Q: What benefits does the high-grade alloy steel construction offer?

A: The use of high-grade alloy steel ensures exceptional durability, shock resistance, and a corrosion-resistant finish, which extends the service life and maintains reliable performance under demanding conditions.Q: Where can Reversing Gears be used most effectively?

A: These gears are widely applied in marine engines, industrial machinery, and automotive setups, providing efficient reversing and transmission in both indoor and outdoor environments.Q: What is the process for ordering and receiving Reversing Gears?

A: Customers can place their orders directly with reputable manufacturers, suppliers, or traders. After order confirmation, products are dispatched and dropped off at the specified destination, typically within a standard delivery timeline.Q: When should the Reversing Gear be serviced or maintained?

A: The gear is designed for minimal maintenance, thanks to its oil-immersed lubrication and robust build. Routine checks and servicing are suggested as per usage frequency, generally after extended operating periods.Q: How does overload protection enhance safety during usage?

A: Built-in overload protection safeguards the gear system from excessive stress, preventing mechanical faults and ensuring user safety during operation in high-demand environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Alum Jar Test Apparatus Electrically Operated

Automation Grade : Electrically Operated

Equipment Materials : Metal and Glass

Type : Jar Test Apparatus

Usage : Water treatment and coagulation testing

Core Components : Heating Element Rotating Paddles

Feature : Uniform heating and paddling

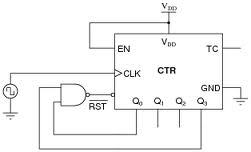

B C D Counter

Automation Grade : Automatic

Equipment Materials : Standard electronic materials (ICs resistors etc.)

Type : Counter Module

Usage : Counting applications in digital electronics

Core Components : CTR Module Resets Input Clock

Feature : Binary Counter with Reset and Clock Input

Electric Arc Furnance

Automation Grade : Semiautomatic

Equipment Materials : Heavyduty steel and refractory materials

Type : Electric Arc Furnace (EAF)

Usage : Melting and refining of metals

Core Components : Electrodes furnace roof refractory lining

Feature : Efficient melting of metals; controlled thermal processing

Stirrer

Automation Grade : Manual

Equipment Materials : Stainless Steel Plate with High Grade Plastic Body

Type : Laboratory Magnetic Stirrer

Usage : Mixing and Stirring Laboratory Solutions

Core Components : Motor, Magnetic Plate, Control Knob

Feature : Variable Speed Control

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry