Model, Turbine:

Model, Turbine: Specification

- Power Source

- Hydraulic (Water Turbine)

- Model No

- Model Turbine

- Accuracy

- 2%

- Core Components

- Rotor, Generator, Shaft

- Frequency

- 50/60 Hz

- Equipment Materials

- High Grade Alloy Steel

- Type

- Horizontal & Vertical Axis

- Usage

- Industrial and Power Generation

- Dimension (L*W*H)

- Customized as per requirement

- Control Panel

- Included

- Blade Material

- Stainless Steel / Special Alloy

- Lubrication

- Automatic

- Surface Treatment

- Rust Proof Coating

- Cooling System

- Air / Water Cooled

- Noise Level

- Low (< 75 dB)

- Life Expectancy

- 20+ Years

- Protection Level

- IP55

About Model, Turbine:

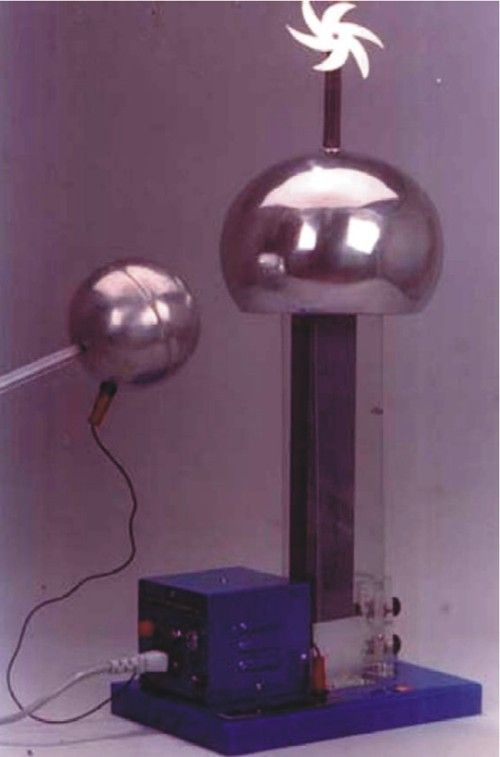

Model Turbine

Demonstrates the working of water turbine for generation of electric power as in hydro-power stations. When water is made to fall on the vanes of turbine from inlet at the top, it makes the vanes of the turbine to rotate and escapes from the outlet at the bottom. A dynamo coupled to the shaft of the turbine rotates with it resulting in conversion of mechanical energy of rotation into electrical energy, which can be observed from the glow of indicator lamp. Both the inlet and outlet have serrated tubulatures for flexible tubing connections. Mounted on base.

Superior Durability and Longevity

Constructed with stainless steel and special high-grade alloys, the Model Turbine is designed for maximum durability and corrosion resistance. A rust-proof coating further extends its operational life, surpassing 20 years, even in demanding industrial settings or power plants.

Efficient and Quiet Operation

Operating at noise levels below 75 dB, this turbine is suited for installations where minimal noise pollution is essential. The combined air/water cooling options and automatic lubrication system ensure optimal performance with minimal maintenance.

Flexible Design for Diverse Applications

Whether your site demands a horizontal or vertical axis model, this turbine can be customized in dimensions and configuration. It is suitable for hydropower generation in various scales, driven by a hydraulic (water) power source and engineered to your specifications.

FAQs of Model, Turbine::

Q: How does the Model Turbine maintain such a low noise level during operation?

A: The turbine is engineered with precise mechanisms and utilizes high-quality materials. The combined use of air or water cooling and well-balanced components minimizes vibration and friction, thus maintaining noise levels below 75 dB during regular operation.Q: What are the main benefits of using stainless steel and special alloys for the turbine blades?

A: Stainless steel and special alloys provide exceptional corrosion resistance, high tensile strength, and durability, which ensure the blades can withstand harsh operating conditions and offer consistent performance throughout their extended lifespan.Q: When is it advisable to use air cooling versus water cooling for this turbine?

A: Air cooling is typically preferred for installations with lower heat generation or where water resources are limited, while water cooling is suitable for high-capacity operations or environments with higher ambient temperatures to better dissipate heat.Q: Where can this model be installed and used effectively?

A: The Model Turbine is suitable for a wide range of industrial and power generation settings, including hydroelectric plants, manufacturing facilities, and any site requiring reliable hydraulic (water-powered) generation with customizable dimensions and robust environmental protection (IP55 rated).Q: What is the process for customizing the dimensions of the turbine to fit specific site requirements?

A: Upon consultation, our engineering team assesses your sites specifications and requirements. They will then design and manufacture the turbine with customized dimensions for length, width, and height, ensuring seamless integration and optimal performance.Q: How does the automatic lubrication system benefit the turbines performance and maintenance?

A: The automatic lubrication system ensures that all moving parts are continuously and efficiently lubricated, reducing wear, minimizing maintenance needs, and promoting consistent performance over the turbines 20+ year lifespan.Q: What core components are included in this turbine, and how do they contribute to its efficiency?

A: The Model Turbine includes a rotor, generator, and shaft as its core components. Their precise engineering and high-quality materials ensure efficient energy conversion, stable power output, and minimal operational losses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PHYSICS LABORATORY EQUIPMENT Category

LEYDEN JAR

Usage : Demonstration of static electricity principles

Dimension (L*W*H) : Not available

Model No : Not available

Type : Electrostatic Storage Device

Core Components : Glass Metal

Weight : Not available

ACCESSORIES FOR SPECTROMETER

Usage : Laboratory

Dimension (L*W*H) : Not Specified

Model No : Not Specified

Type : ACCESSORIES FOR SPECTROMETER

Core Components : Spectrometer attachments, sample holders, wavelength filters

Weight : Not Specified

Van de Graff Generator, Motor Driven

Usage : Laboratory

Dimension (L*W*H) : 30 cm x 15 cm x 50 cm

Model No : VDG200MD

Type : Motor Driven Van de Graff Generator

Core Components : Belt, electrode, acrylic base, motor

Weight : 9 Kg

GOLD LEAF ELECTROSCOPE

Usage : Used in physics laboratories for experiments and demonstrations

Dimension (L*W*H) : Approximately 15cm x 10cm x 10cm

Model No : GLE01

Type : Electroscope

Core Components : Metal rod gold leaf insulated casing

Weight : Approximately 500 grams

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry