Maxwell Vibration Needle

Maxwell Vibration Needle Specification

- Accuracy

- High Frequency Vibration for Better Compaction

- Frequency

- 50 Hz

- Model No

- MVN-1500

- Voltage

- 220 V

- Core Components

- Needle Shaft, Vibrator Head, Flexible Shaft, Motor Housing

- Power Source

- Electric Motor

- Capacity

- 1.5 HP

- Temperature Range

- Not Specified

- Automation Grade

- Manual

- Equipment Materials

- Heavy Duty Steel Shaft, Hardened Needle Tip

- Type

- Maxwell Vibration Needle

- Usage

- Concrete Compaction

- Dimension (L*W*H)

- 38 x 8 x 8 cm (Needle Length x Shaft Diameter x Head Diameter)

- Weight

- 10 kg (Approx)

About Maxwell Vibration Needle

Maxwell Vibration Needle: Competitive Advantages & Features

Maxwell Vibration Needle stands out for its heavy-duty steel shaft and hardened needle tip, ensuring durability and outstanding compaction performance. Immaculate vibration at 12,000 RPM provides high accuracy for concrete slab, column, and beam work. The integrated transport handle simplifies movement across job sites. Quick coupling, an air-cooled motor, low noise output, and built-in overload protection elevate user experience. This manual, electric-powered tool is ideal for professionals seeking efficient, high-capacity operation for modern construction projects.

Certifications, Samples & Order Support for Maxwell Vibration Needle

Maxwell Vibration Needle is manufactured and supplied under rigorous standards, ensuring consistent product valuation and reliability. We facilitate order processing and transportation of certified equipment across India. Sample units are available for preliminary evaluation, subject to our transparent sample policy, which prioritizes customer trust and satisfaction. Whether you are a contractor or a trading partner, our procedures ensure smooth order fulfillment, reliable performance assessment, and timely support for all your construction supply needs.

FAQs of Maxwell Vibration Needle:

Q: How does the Maxwell Vibration Needle improve concrete compaction?

A: The Maxwell Vibration Needle operates at a high frequency of 12,000 RPM to deliver outstanding vibration performance, which removes air pockets and ensures immaculate, dense, and durable concrete compaction in slabs, columns, and beams.Q: What types of construction projects is the Maxwell Vibration Needle suitable for?

A: It is ideal for use in various construction settings, especially for compacting concrete in slabs, beams, and columns, offering both accuracy and high efficiency in building projects.Q: Where can I order the Maxwell Vibration Needle, and is sample evaluation possible?

A: You can order the Maxwell Vibration Needle directly through authorized manufacturers, suppliers, or traders in India. Sample evaluation is available, following our sample policy for product valuation and customer satisfaction.Q: What are the safety features included with this device?

A: The device is equipped with overload protection for operator safety and durability, as well as an integrated cooling system to maintain optimal operating conditions and prevent overheating during prolong use.Q: How is the Maxwell Vibration Needle transported and handled on-site?

A: It features an integrated transport handle and compact build, allowing for easy and safe movement around construction sites, enhancing both convenience and efficiency during transportation and operation.Q: When can I expect delivery after placing an order?

A: Delivery timing is subject to current stock availability and transportation schedules, but our streamlined order processing system ensures prompt shipment to meet project deadlines in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

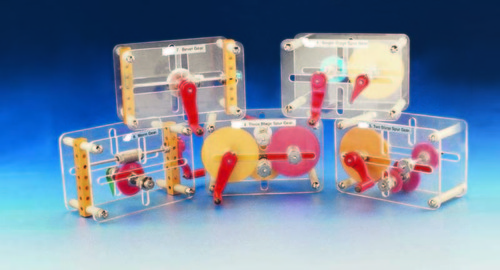

More Products in APPLIED MECHANICS Category

Anti-Priming Pipe

Core Components : PVC HDPE

Type : Pipe

Usage : Fluid flow regulation in industrial applications

Equipment Materials : Plastic

Weight : Lightweight

Automation Grade : Manual

Collar Beam Truss Model

Core Components : Wood beams and connectors

Type : Structural Truss

Usage : Support structures for roofs and ceilings

Equipment Materials : Wood

Weight : Depends on material and design specifications

Automation Grade : Manual

Spur Gears

Core Components : Teeth, Hub, Bore

Type : Spur Gear

Usage : Industrial machinery, automation, conveyors, gearboxes

Equipment Materials : Alloy Steel, Cast Iron, Carbon Steel, Stainless Steel

Weight : 1 kg to 35 kg

Sellers Coupling

Core Components : Body (Coupling), Seal Gasket, Locking Clamps

Type : Sellers Coupling

Usage : Quick and secure connection of pipes for fluid transfer; widely used in fire fighting, irrigation, and industrial applications

Equipment Materials : Carbon Steel, Stainless Steel, Brass, or as specified by application

Weight : Varies as per size and material

Automation Grade : Manual

GST : 06ACOPS0805K1ZD

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry