Float Steam Trap

Float Steam Trap Specification

- Core Components

- Float mechanism Condensate discharge valve

- Automation Grade

- Automatic

- Capacity

- 20 kg/h

- Feature

- Reliable condensate discharge energy-efficient

- Temperature Range

- Up to 300C

- Model No

- FT-100

- Warranty

- 12 months manufacturing warranty

- Measurement Range

- Up to 10 bar

- Power Source

- No external power required

- Accuracy

- High

- Equipment Materials

- Cast iron stainless steel

- Type

- Float Steam Trap

- Usage

- Steam system condensate removal

- Dimension (L*W*H)

- 150 x 100 x 80 mm

- Weight

- 2.5 kg

About Float Steam Trap

FAQs of Float Steam Trap:

Q: What is the warranty coverage for the Float Steam Trap (model no. FT-100)?

A: The Float Steam Trap comes with a 12-month manufacturing warranty.Q: Does the Float Steam Trap require an external power source for operation?

A: No, the Float Steam Trap does not require any external power source.Q: What are the equipment materials used in the construction of the Float Steam Trap?

A: The Float Steam Trap is made of cast iron and stainless steel.Q: Is the Float Steam Trap suitable for high-pressure applications?

A: Yes, the Float Steam Trap has a measurement range of up to 10 bar, making it suitable for such applications.Q: How does the Float Steam Trap ensure reliable condensate discharge?

A: The Float Steam Trap features a float mechanism and a condensate discharge valve as core components to ensure reliable condensate discharge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

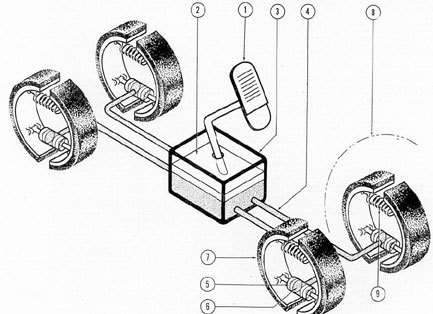

Hydraulic Break Unit

Automation Grade : SemiAutomatic

Core Components : Hydraulic Cylinder Brake Pedal Tubing

Feature : Precision Control Durable

Capacity : 500 kg

Type : Hydraulic Brake Unit

Temperature Range : 20C to 80C

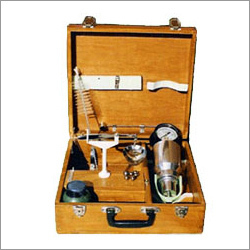

Rapid Moisture Meter

Automation Grade : Manual

Core Components : Stainless steel body heating element pressure gauge

Feature : Portable moisture measurement

Capacity : 50 grams

Type : Moisture Meter

Temperature Range : Ambient to 150C

Slide Crank Mechanism

Automation Grade : Manual

Core Components : Metal rods and hinges

Feature : Conversion of rotary motion into linear motion

Capacity : Single mechanism

Type : Mechanical demonstration model

Temperature Range : Room temperature usage

Epicycle Gear

Automation Grade : Manual

Core Components : Gear Assembly

Feature : Epicyclic motion mechanism

Capacity : Standard

Type : Epicycle Gear

Temperature Range : 20C to 80C

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry