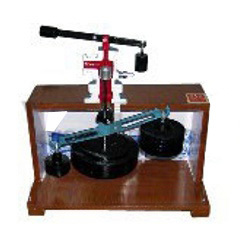

Flexible Coupling

Flexible Coupling Specification

- Power Source

- Mechanical

- Feature

- High Torque Capacity, Misalignment Compensation

- Core Components

- Flexible Element, Hub

- Automation Grade

- Manual

- Equipment Materials

- Cast Iron / Steel / Rubber / PU

- Type

- Flexible Coupling

- Usage

- Power Transmission, Absorbs Shock & Vibration

- Dimension (L*W*H)

- Standard sizes from 50mm to 200mm (Diameter)

- Finish

- Black Phosphated / Painted

- Insert Material

- Rubber / Polyurethane

- Resistant To

- Oil, Grease, Some Acids

- Noise Level

- Low

- Max Speed

- 5000 RPM

- Bore Size Range

- 12mm to 60mm

- Application

- Motors, Pumps, Gearboxes, Conveyors

- Shaft Coupling Method

- Clamp / Set Screw

About Flexible Coupling

Versatile Applications for Premier Performance

Our flexible coupling is tailored for use in motors, pumps, gearboxes, and conveyors, making it ideal for diverse industrial sectors. It offers exceptional performance with various application media and is suitable for oil, grease, and certain acids. The coupling is designed for power transmission and excels in environments where low noise and reliable vibration absorption are paramount. Its compatibility with mechanical power sources makes it a go-to choice for professionals demanding reliability in demanding applications.

Premium Supply Ability and Swift Delivery Logistics

We pride ourselves on our substantial supply capacity, ensuring steady availability of this superlative flexible coupling. Ready-to-ship samples can be provided for testing and approval. Our logistics team guarantees premium service and quick dispatch times, minimizing waiting periods and meeting urgent requirements reliably. From order confirmation to final delivery, our streamlined process ensures your projects maintain momentum with the support of dependable delivery schedules and responsive order management.

FAQs of Flexible Coupling:

Q: How does a flexible coupling benefit power transmission systems?

A: A flexible coupling absorbs shocks and vibrations, compensates for misalignment, and enables smooth power transfer between shafts, thereby extending equipment life and minimizing downtime in power transmission applications.Q: What is the process for selecting the correct flexible coupling size?

A: To select the appropriate flexible coupling, determine the shaft diameter (12mm60mm), desired torque capacity, operating speed, and environmental factors such as exposure to oils or acids. Consult the provided specifications to ensure compatibility with your equipment.Q: When should a flexible coupling be used instead of a rigid coupling?

A: Flexible couplings are ideal when you need to accommodate shaft misalignment, dampen vibrations, or absorb shocks. They are particularly useful in applications involving motors, pumps, gearboxes, and conveyors where movement or vibration is expected.Q: Where can this flexible coupling be installed?

A: This coupling can be installed in industrial environments requiring robust power transmissionsuch as manufacturing plants, processing units, or conveyor setupsespecially where oil, grease, or some acids may be present.Q: What makes your flexible coupling a premium product?

A: Our coupling features a durable cast iron or steel hub, high-quality rubber or polyurethane insert, special finishes for corrosion resistance, and first-rate misalignment compensation, ensuring superlative performance and reliability in demanding environments.Q: How can samples be obtained for evaluation?

A: Samples are available upon request. Contact our team to arrange for a test unit. Our logistics process ensures quick dispatch so you can evaluate the couplings suitability for your needs promptly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Moisture Meter For Wood

Automation Grade : Manual

Feature : Fast and Accurate Moisture Measurement

Usage : Wood Moisture Measurement

Type : Moisture Meter for Wood

Core Components : Sensor Display

Power Source : Battery Operated

Sunshine Recorder Model

Automation Grade : Manual

Feature : Records sunlight hours

Usage : Measurement of sunlight duration

Type : Meteorological Instrument

Core Components : Brass components

Power Source : No external power required

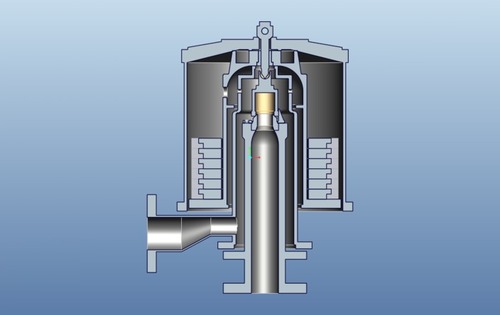

Dead Weight Safety Valve

Automation Grade : Manual

Feature : Pressure Relief

Usage : Steam Boiler and Pressure Systems

Type : Dead Weight Safety Valve

Core Components : Valve Dead Weight Assembly

Power Source : Not Required

Combined High Steam And Low Water Safety Valve

Automation Grade : Manual

Feature : Automatic pressure release and low water safety

Usage : Steam Boilers, Pressure Vessels, Industrial Applications

Type : Combined High Steam and Low Water Safety Valve

Core Components : Valve Body, Spring, Seat, Spindle

Power Source : Not Required (Mechanical)

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry