Feed Check Valve

Feed Check Valve Specification

- Power Source

- Manual Operation

- Model No

- FCV-102

- Core Components

- Body, Cover, Seat, Spindle

- Frequency

- 50-60 Hz

- Automation Grade

- Manual

- Accuracy

- 1%

- Temperature Range

- -20C to 220C

- Capacity

- Up to 6000 Kg/hr

- Measurement Range

- 0.5 to 50 bar

- Feature

- Non-Return, Leakage Proof

- Equipment Materials

- Cast Iron, Stainless Steel

- Type

- Feed Check Valve

- Usage

- Boiler Feed Water Line

- Display Type

- Analog

- Dimension (L*W*H)

- 230mm x 185mm x 155mm

- Weight

- 8.5 kg

- Size Range

- 15 mm to 200 mm (1/2" to 8")

- Media

- Steam, Water, Air, Non-corrosive fluids

- Flow Direction

- Unidirectional

- Seat Type

- Metal/Soft Seated

- Max Working Pressure

- 40 bar

- Testing Pressure

- 1.5x working pressure

- End Connection

- Screwed/Flanged/Socket Weld

- Surface Finish

- Anti-corrosive coating

- Connection Type

- Flanged/Threaded

- Application

- Industrial boilers, steam lines, water treatment plants

About Feed Check Valve

Application & Usage: Feed Check Valve Advantages

This Feed Check Valve serves as a critical component in industrial boilers, water treatment plants, and steam lines. Used primarily to regulate feed water flow and prevent backflow, it operates unidirectionally with manual precision. Key features include a leakage-proof, anti-corrosive surface, and compatibility with multiple media such as steam, air, and water. Its robust construction ensures dependable service in demanding environments, supported by blue-ribbon metal or soft-seated options and choice of end connections.

Sample Policy & Delivery: Seamless Procurement Experience

We offer a customer-centric sample policy, providing sample Feed Check Valves for evaluation before full-scale procurement. Quick dispatch and secure transportation are guaranteed, ensuring timely delivery to your facility. With samples available across the main domestic market, our streamlined process aids in expediting project timelines. Trust us for swift logistics and seamless handling from order placement to final delivery, ensuring your industrial operations benefit from our products without unnecessary delay.

FAQs of Feed Check Valve:

Q: How does the Feed Check Valve ensure leakage-proof operation?

A: The Feed Check Valve features a precision-engineered seal, available in metal or soft-seated options, coupled with an anti-corrosive coating. This combination effectively prevents leakage under high pressure and various media, safeguarding your system integrity.Q: What are the recommended applications for this valve?

A: This valve is specifically designed for use in industrial boilers, steam lines, and water treatment plants. It efficiently controls the flow of steam, water, air, and other non-corrosive fluids, ensuring optimal equipment protection and process reliability.Q: Where can I procure sample units of the Feed Check Valve?

A: Sample units are available upon request through our sample policy. We ensure timely delivery and quick dispatch to clients across India, enabling you to evaluate product suitability before placing bulk orders.Q: What is the process for installing the Feed Check Valve in industrial systems?

A: Installation is straightforward, with options for flanged, threaded, or socket-weld connections. Our technical guidance facilitates proper integration into boiler feed water lines or similar setups, ensuring seamless performance.Q: What benefits do the anti-corrosive surface and robust construction offer?

A: The anti-corrosive surface finish extends valve lifespan and minimizes maintenance, while the robust cast iron or stainless steel body delivers reliability under demanding conditions and high-pressure environments, offering exceptional value and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

Robinson's Cup Anemometer (with flash light)

Feature : Flashing light for visibility

Type : Cup Anemometer

Usage : Wind Speed Measurement

Automation Grade : SemiAutomatic

Core Components : Metal Plastic

Equipment Materials : Aluminum Polycarbonate

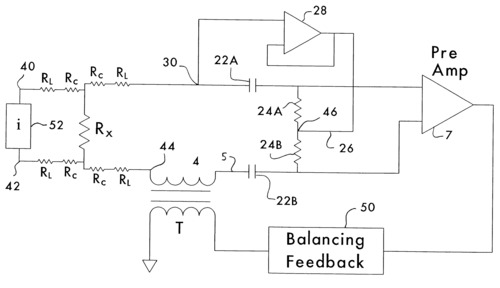

A.C.Impendance Bridge

Feature : Balancing Feedback System

Type : Laboratory Instrument

Usage : Impedance measurement and calibration

Automation Grade : Manual

Core Components : Transformer Resistors Amplifiers

Equipment Materials : Copper Aluminum Plastic

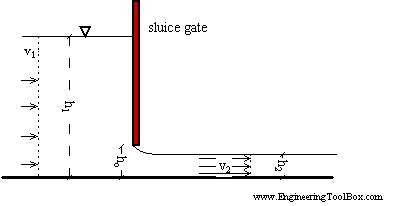

Sluice Gate

Feature : Used for controlling water flow in canals and dams

Type : Vertical gate

Usage : Water flow management in irrigation systems flood control and industrial settings

Automation Grade : Manual/Automatic

Core Components : Hydraulic system Gate leaf Frame

Equipment Materials : Stainless Steel Mild Steel Cast Iron

Cylindrical Measures IS :2386

Feature : Durable and Corrosion Resistant

Type : Cylindrical Measures

Usage : Aggregate Testing in Laboratories

Automation Grade : Manual Operation

Core Components : Metal Container

Equipment Materials : HighGrade Steel

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry