Cyclodial Gear

Cyclodial Gear Specification

- Feature

- High Torque, Compact Design, Low Noise, High Reliability

- Capacity

- As per requirement (customized)

- Power Source

- Electric Motor Driven

- Voltage

- 220415 V AC

- Frequency

- 50/60 Hz

- Model No

- CG Series

- Core Components

- Cycloidal Disc, Needle Bearings, Input Shaft, Output Shaft

- Type

- Cycloidal Gear Reducer

- Usage

- Industrial Machinery, Automation, Robotics, Conveyors

- Dimension (L*W*H)

- Varies by model

- Weight

- Varies by model (approx. 15500 kg)

About Cyclodial Gear

Versatile Industrial Performance and Usage

Cyclodial Gear units are engineered for versatile use in industrial machinery, automation systems, robotics, and conveyor applications. They can be foot, flange, or shaft mounted, allowing integration according to your specific set-up. As electric motor driven reducers, they provide high torque transfer in compact, efficient formats suitable for continuous operation. Customize dimensions and capacities to fit your exact processing or manufacturing requirementsthese gears are ideal for users seeking reliable, adaptable transmission solutions across demanding environments.

Sample Policy, Payment, and Reliable Shipment

Our premium Cyclodial Gear sample policy is straightforwardclients can request a product sample to evaluate suitability before making bulk orders. Payment terms are flexible to support a smooth transaction process, ensuring your investment aligns with your procurement plans. Every order enjoys robust supply ability, and goods are handed over with secure packaging and prompt shipment, giving peace of mind that you will receive your gearboxes undamaged and on schedule, ready to power your industrial operations.

FAQs of Cyclodial Gear :

Q: How do I select the appropriate Cyclodial Gear model for my application?

A: To choose the suitable Cyclodial Gear model, consider your required output torque, reduction ratio, mounting type, input speed, and environmental protection class (IP54 or IP65). Our sales engineers are available to help you find the perfect fit for your equipment specifications and operational demands.Q: What applications are Cyclodial Gears typically used for?

A: Cyclodial Gears are commonly employed in industrial machinery, automation setups, conveyor systems, and robotics. Their compact, high-torque design makes them ideal for demanding operations requiring robust, reliable power transmission.Q: When can I expect my Cyclodial Gear shipment after placing an order?

A: After confirming your order and payment, the Cyclodial Gear is typically handed over to the shipping partner promptly. Delivery times vary based on customization and location, but we prioritize fast, safe shipment to meet your operational deadlines.Q: Where are these Cyclodial Gears manufactured and supplied from?

A: All CG Series Cyclodial Gears are manufactured, supplied, and traded directly from our advanced facility in India, ensuring quality control and efficient logistics for both domestic and international shipments.Q: What is the benefit of using Cyclodial Gears with high shock load capacity?

A: Cyclodial Gears with high shock load capacityup to 500% of rated torqueoffer enhanced durability under abrupt load changes, reducing the risk of mechanical failure and extending operational life in demanding applications.Q: How does the sample policy work for Cyclodial Gear orders?

A: Our sample policy allows clients to request Cyclodial Gear samples before committing to larger orders. This approach ensures you can test performance and compatibility without full investment upfront, promoting confident purchasing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in APPLIED MECHANICS Category

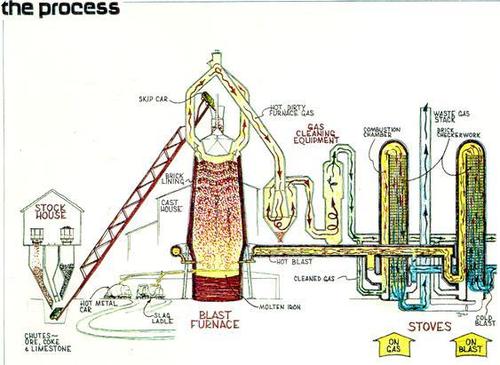

Blast Furnance

Automation Grade : Automatic

Core Components : Steel body refractory lining

Dimension (L*W*H) : Customizable dimensions

Equipment Materials : Steel cast iron refractory bricks

Model No : BFStandard01

Warranty : 12 years

Rain Gauge Recording Type

Automation Grade : Manual

Core Components : Cylindrical body Recording mechanism

Dimension (L*W*H) : Height: approximately 50 cm Diameter: approximately 20 cm

Equipment Materials : Metal body

Model No : RG01

Warranty : 1year warranty

Triangular Eccentric Cam

Automation Grade : Manual

Core Components : Steel Aluminum

Dimension (L*W*H) : 50 cm x 30 cm x 20 cm

Equipment Materials : Metal

Model No : TEC101

Warranty : 1 Year

Le-chetelier Mould

Automation Grade : Manual

Core Components : Brass Steel

Dimension (L*W*H) : Standard dimensions as per ASTM C151

Equipment Materials : Brass body with steel rods

Model No : LCM001

Warranty : 1 year

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry