BAR AND GAUGE

BAR AND GAUGE Specification

- Feature

- Corrosion Resistant, Accurate Reading

- Model No

- Standard Gauge

- Core Components

- Bourdon Tube, Dial, Pointer

- Automation Grade

- Manual

- Power Source

- Not required (Mechanical)

- Equipment Materials

- Stainless Steel/Brass

- Type

- Bar Gauge

- Usage

- Pressure Measurement

- Dimension (L*W*H)

- 63mm (Dial Diameter)

- Weight

- Approx. 200g

- Application

- Industrial & Laboratory, Pneumatic & Hydraulic Systems

- Connection Type

- Bottom Connection

- Protection Class

- IP45

- Casing

- Stainless Steel Casing

- Mounting

- Direct Mount

- Operating Pressure

- Up to 25 bar

- Dial Color

- White with Black Markings

- Thread Size

- 1/4'' BSP

About BAR AND GAUGE

BAR AND GAUGE

Demonstrates thermal expansion of metals. A flat, metal, U shaped gauge with a GO/NO-GO hole at one end. A metal bar with stem at center has a wooden handle. End of metal bar, when cold, passes easily through hole of gauge, but does not pass through same hole when heated.

Corrosion Resistant for Long-Lasting Performance

The stainless steel and brass construction offer remarkable resistance to corrosion, ensuring the gauge remains functional even in harsh industrial environments. This robust build is ideal for locations where chemical exposure or moisture is prevalent, maximizing reliability and minimizing maintenance requirements.

Accurate Readings for Precision Applications

Equipped with a high-quality Bourdon tube and clearly marked dial, the BAR AND GAUGE provides consistently accurate pressure readings. It is suitable for both pneumatic and hydraulic systems, ensuring safe and efficient operation in laboratories and industrial settings where precision is critical.

Direct Mount and Versatile Installation

Featuring a standard 1/4 BSP bottom connection and direct mounting design, the gauge integrates seamlessly into a wide variety of equipment setups. Its compact size and manual operation make it highly adaptable for new installations or replacements in both legacy and modern systems.

FAQs of BAR AND GAUGE:

Q: How do I install the BAR AND GAUGE with a bottom 1/4 BSP connection?

A: To install, ensure the system is depressurized, attach the gauge to the designated bottom-mounted port using the 1/4 BSP threaded connection, and tighten securely. The process supports direct mounting for easy integration into pneumatic or hydraulic setups.Q: What operating pressure range does this gauge support?

A: The BAR AND GAUGE can accurately measure pressures up to 25 bar, making it suitable for a wide variety of industrial and laboratory applications involving pneumatic and hydraulic systems.Q: When should I use a mechanical bar gauge instead of an electronic one?

A: A mechanical bar gauge like this Standard Gauge is preferred when you need a rugged, power-free solution for reliable and accurate pressure readings, especially in environments lacking electrical sources or where maintenance should be minimized.Q: Where is this type of gauge commonly used?

A: This gauge is widely used in India for industrial machinery, laboratory setups, and hydraulic or pneumatic systems, owing to its robust material construction and direct mount design.Q: What is the benefit of stainless steel casing on the gauge?

A: The stainless steel casing ensures excellent durability and resistance to corrosion, making the gauge suitable for demanding environments and extending service life with minimal upkeep.Q: How does the gauge provide accurate readings without a power source?

A: It utilizes a Bourdon tube mechanism, dial, and pointermechanically driven by system pressureso it does not require any electrical power, allowing for dependable operation in manual and automated workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PHYSICS LABORATORY EQUIPMENT Category

HARE'S APPARATUS

Automation Grade : Manual

Feature : Used to compare densities of liquids

Core Components : Glass tube Wooden support Rubber tubing

Measurement Range : Up to 2 liquids

Equipment Materials : Glass Wood Rubber

Usage : Liquid density comparison in laboratories

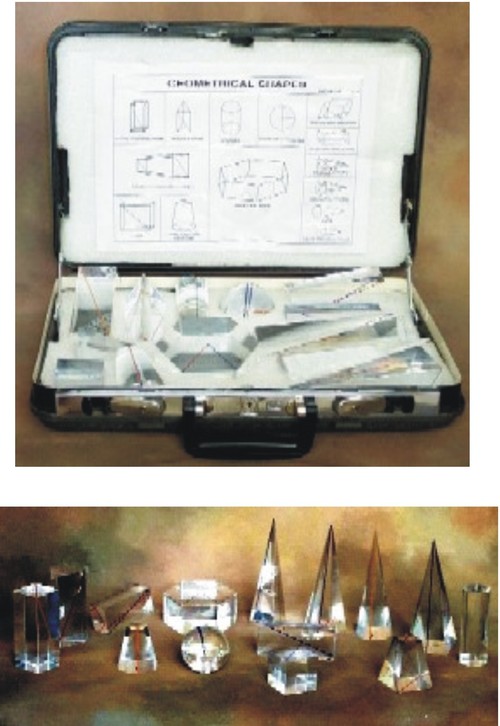

Geometrical Set, Acrylic

Automation Grade : Manual

Feature : Transparent precise geometrical shapes

Core Components : Acrylic

Measurement Range : Multiple shapes and sizes

Equipment Materials : Highquality acrylic

Usage : Educational purposes teaching geometry labs

INTERCHANGEABLE SCALES FOR DEMONSTRATION METER

Automation Grade : Manual, No Automation

Feature : Interchangeable scales for easy switching of ranges and quantities

Core Components : Printed Measurement Scale

Measurement Range : Varies1A, 1V, 10V, 100V, and more

Equipment Materials : Printed Card/Plasticized Paper

Usage : Demonstration and Laboratory Education

OPTICAL BENCH, METAL

Automation Grade : Manual

Feature : Durable Stable Base

Core Components : Metal Rod Clamps Supports

Measurement Range : Up to 100 cm

Equipment Materials : Metal

Usage : Optical Experiments and Measurements

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry